Waterproof without fluorocarbons

Performance meets Ecology

95% of the VAUDE Summer 2017 Apparel Collection and 100% of the 2018 Summer Collection are PFC-free.

Fluoro-what? What's the problem with fluorocarbons anyway?

To put it simply:

Fluorocarbons don't occur naturally on our planet. These are polyfluorinated or perfluorinated compounds, also referred to as PFC or PFOS . They were invented in the 1960s and have been used since then for a variety of applications, for example as a chemical finish on textiles to make them waterproof, stain resistant and oil repellent. PFCs are also used in many other industrial areas.

Hazardous substances made by humans

The real problem is that later, it was discovered that PFCs are harmful to the environment and to human health. For example, PFOA (perfluorooctanoic acid) is one of the most critical substances:

This substance doesn't occur in nature either, but it's been found in breast milk, the blood of polar bears, in glaciers, on every continent of the planet and even in our drinking water.

Development and distribution of PFCs

PFOA is created in the production process based on C8 technology. C8 stands for eight carbon atoms (carbon = C). Grossly simplified, these carbon atoms are replaced by fluorine atoms (all = per, some = polyfluorinated). This makes an extremely stable and dangerous molecule – PBT substances:

- P = persistent: does not degrade, or degrades very slowly

- B = bioaccumulative: accumulates through the food chain in the body, usually in the blood or in the liver.

- T = toxic

Not exactly a chemical you want to have around. There are many studies about the serious health consequences of PFC in the body, including cancer.

The global water cycle transports PFCs everywhere

If a rain jacket was waterproofed with C8, traces of PFOA can be found in it. Whether or not, or the degree to which, this is dangerous for the wearer is still controversial. But in any case, it is clear that in the manufacturing process of PFC and the materials treated with it, PFC escapes into the environment, primarily by means of industrial wastewater.

Because all of the earth’s water is moving around in a huge, endless cycle of evaporation, rain, ocean currents, etc., PFCs are spread around the planet. We've already known this for a long time, but it was the Greenpeace Detox Campaign to first raise the public’s awareness of the issue.

The EU is considering a ban on perfluorooctanoic acid (PFOA ), but so far there are only legal limits in Norway. Therefore, PFCs continue to be processed legally.

So we believe that it is all the more important for us to take on responsibility as an outdoor brand and to voluntarily eliminate the use of all PFCs in our products as quickly as possible.

100% PFC-free thanks to VAUDE Eco Finish

We need waterproofing: Textile surfaces are waterproofed with durable water repellency (DWR) to repel water and dirt. Without this surface treatment, the outer fabric would absorb rainwater which leads to a clammy microclimate even if the product has a waterproof membrane.

In the past, it was technically nearly impossible to produce an equivalent high-performance waterproofing without PFCs. Thanks to innovative technologies this is now no longer a problem.

The fact is, however, that oil repellency on fabrics is achieved only with the help of PFC. We have thoroughly examined this issue of whether outdoor products really need this feature and decided that for VAUDE, they do not – for the planet and for all of us.

VAUDE takes responsibility and has voluntarily undertaken a commitment to manufacture its entire collection completely PFC-free by the year 2020 – apparel by 2018.

Green Shape Eco Finish - Movie:

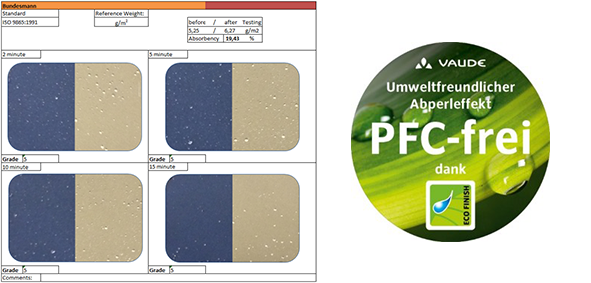

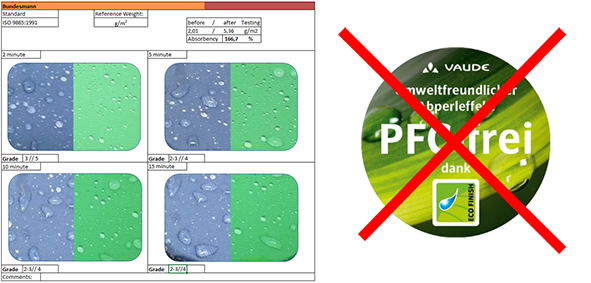

Rigorous testing for products: Spray Test and the Bundesmann test

For years, our VAUDE Materials Team has been testing which PFC-free DWR offers the best water beading effect on which materials. The Spray Test is standard for this. In addition we always test abrasion resistance and washing resistance of DWR, and how much water the material absorbs during a simulated heavy rain in accordance with the Bundesmann test.

Decision pro Eco Finsih

Cyclist Jacket

Decision contra Eco Finish

Escape Light Jacket

This is a long and complex process, which we are promoting together with the manufacturers of materials and the DWR chemicals along with experts from universities and industry associations. We use only the materials that offer full performance in our collections. After all, nobody wants to get wet either...

We are proud of the fact that we now have successfully converted many of our materials to PFC-free DWR:

The share of our PFC-free apparel products (i.e. products without DWR and Eco Finish waterproofed products) in the 2017 Summer Collection is 95% and in the 2018 Summer Collection it's 100%!

Percent of Eco Finish (PFC-free) for waterproof and water repellent products per season and product range

Create your own infographicsEco Finish for best performance

Together with our suppliers, we draw on a full portfolio of fluorocarbon free alternatives that have proven reliable on our materials. Since not every technology functions just as well on each kind of material, we have a variety of options from different vendors.

VAUDE Eco Finish covers all fluorocarbon-free technologies that are processed in our VAUDE products.

Our VAUDE website has a special filter so that you can easily find our PFC-free products.

C6 as a transitional technology

We waterproof the products for which we have found still no functional Eco Finish DWR with a C6 DWR.

C6 is considered to be a more environmentally friendly alternative to C8. It contains six carbon atoms and does not create PFOA. But because C6 has shorter molecule chains, it is more mobile and spreads faster than C8 via the global waterways. It is really only a stop-gap technology that we want to replace with Eco Finish as soon as possible.

At VAUDE this applies especially to tents, backpacks and some shoes; until the Winter Collection 2017 there are also still a few apparel models.

The Manufacturing Restricted Substance List applies for VAUDE, which sets strict limits on the use of chemicals. The bluesign® system regulates the use of PFCs very strictly as well.

»It was a feat, but we are proud of the fact that we now have successfully transitioned many of our materials to PFC-free DWR: Starting in summer 2018 our entire Apparel Collection will be made with Eco Finish." Antje von Dewitz, CEO «