Pioneering achievement: all apparel fabrics are PFC-free

In addition to the water-repellent clothing (such as softshell jackets and trekking trousers) that we have been producing completely free of PFC since the summer of 2015, we have now eliminated PFC from all of the outer fabrics of our waterproof products such as rain jackets and rain trousers. For years now, VAUDE has refrained from using PFC for its waterproof membranes.

The only exception: For the time being, we’re still using PFC for the waterproof zips in our high-performance products. As of summer 2019, we will be one of the first outdoor manufacturers to completely elimate the use of PFC for these as well. By 2020 at the latest, we aim to be 100 % PFC-free in all VAUDE products.

When we talk about the use of PFC in outdoor products, we are talking about two things:

Waterproof membranes:

A membrane is used to make clothing waterproof. It is a thin layer that is integrated between fabric layers that keeps water out but is still breathable. PFC is required for the production of most conventional membranes. Since the introduction of the 2011 Winter Collection, we have been using PFC-free membranes exclusively.

Water repellent gear:

The water beading effect, impregnation, Durable Water Repellency or DWR for short: It’s all about getting water and dirt to pearl up on the outer surface of fabrics. Without some kind of treatment, the outer surface of jackets and trousers would soak up rainwater, which would then restrict breathability and lead to a clammy feeling in the clothing despite the waterproof membrane.

PFC-containing chemicals are also frequently used in conventional technologies for this purpose. For years we have intensively researched PFC-free alternatives, carryied out tests of rainwear and softshell products with over 300 different fabrics, and have gradually switched to a PFC-free technology that we call Eco Finish. With the launch of the Spring/Summer Collection 2018, all of our apparel fabrics are 100 % PFC-free with Eco Finish.

»For us, the PFC phase-out for our apparel fabrics was an enormous feat of strength. We mastered this challenge by years of working with our partners from the chemical industry and our material suppliers focusing strongly on the solutions themselves as well as on process reliability and by carrying out countless tests. I am very proud of the fact that today, we can show that it is possible to offer PFC-free alternatives without our customers having to forego important functionality.«

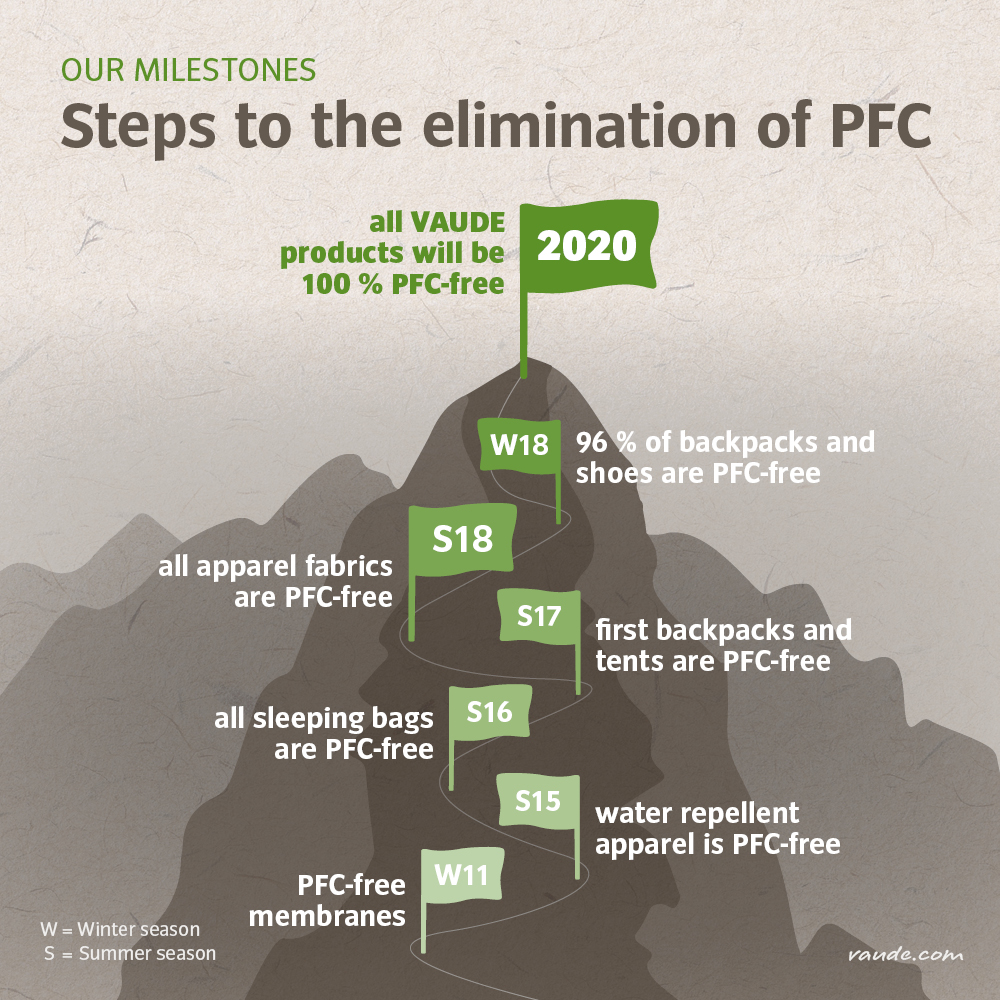

Our milestones / steps to the elimination of PFC

The VAUDE milestones to the gradual elimination of PFC:

- Winter 2011: PFC-free membranes

- Summer 2015: water repellent apparel is PFC-free

- Summer 2016: all sleeping bags are PFC-free

- Summer 2017: first backpacks and tents are PFC-free

- Summer 2018: all apparel fabrics are PFC-free

- Winter 2018: 96 % of backpacks and shoes are PFC-free

- Our goal for 2020: all VAUDE products will be 100 % PFC-free

Our next steps to 2020:

In the Greenpeace Detox agreement, we voluntarily committed ourselves to replacing fluorocarbons in all VAUDE products with environmentally friendly alternatives by 2020. We are well on our way and have already passed the biggest milestones with a complete transition in the treatments for our sleeping bags and all apparel fabrics.

Currently, we are still using materials that contain PFC based on C6 bridge technology for waterproof zips, tents, shoes and backpacks. This coming Fall/Winter Season 2018/19, we will be using a PFC-free finish for 96 % of our shoes and backpacks — the majority of the collection.

Starting in Summer 2019, all waterproof zips in rain jackets and trousers will also be PFC-free. By 2020 at the latest, we want to have completed the entire PFC phase-out for all VAUDE products.

|

Good to know:

All VAUDE products with PFC-free Eco Finish Time to reproof? |

Where else do you come into contact with PFC?

Fluorocarbons are also used in many other areas of our daily life due to their water and fat repellent properties, such as for non-stick coatings in pans, coffee cups or pizza boxes as well as for fire extinguishants, carpets and many building materials. You can find out more about this from the Federal Environment Agency (German)