We are proactive in our fight against hazardous substances

Clear strategy for chemicals management

It is our declared goal to ensure product safety and consumer safety for all of our product groups and to go beyond legal requirements.

The fashion industry is the second most polluting industry, just behind oil. 25 % of the world’s chemicals are used for fashion production. We are working to meet this challenge which is why there is a clear strategy for the management of chemicals at VAUDE.

- We place the highest emphasis on the safety for our customers.

- We refrain from using ecologically harmful and hazardous chemicals.

- Even without legal regulations, we are finding substitutes for dangerous substances.

- We take on comprehensive responsibility for people and the environment in our supply chain.

- We are transparent with all of the chemicals we use.

- We train and empower our partners in the supply chain.

Exceptionally strict limits with the Detox Commitment®

Milestone: switching from the RSL to the MRSL

Create your own infographicsSwitching from RSL to MRSL is a major step. While compliance with limit values was previously observed in finished products only, it is now required throughout the entire manufacturing process including the production of yarns, weaving, dyes, coating/lamination and further finishing steps. This is quite a big step for us, and we also need the cooperation of our supply chain. However, we will continue to follow this path, as it will help us achieve great improvement for the people and the environment near our production sites. The VAUDE MRSL is the basis of our business relationships for all materials used, such as fabrics, components and packaging materials.

The limits and prohibitions of individual substances listed in the VAUDE MRSL go far beyond legal requirements (REACH) and the requirements of other textile standards.

Our MRSL largely corresponds to the MRSL of the Textile Alliance, which is identical to the MRSL of ZDHC (Zero Discharge of Hazardous Chemicals). The ZDHC brings together several leading fashion and sports brands to jointly promote the phase-out of hazardous substances.

Consistent monitoring of the supply chain using the VAUDE MRSL

100 percent of our producers have signed our MRSL. 98 percent of the material manufacturers have signed our MRSL. We are continuing talks with those producers and material manufacturers who have not yet signed the MRSL.

VAUDE Green Shape Products: Suppliers must provide test reports.

Each supplier and producer must confirm compliance with the limits stipulated in the MRSL - and this also includes test reports. For our partners, we have agreed on a VAUDE Hazardous Substances Program with a renowned testing institute.

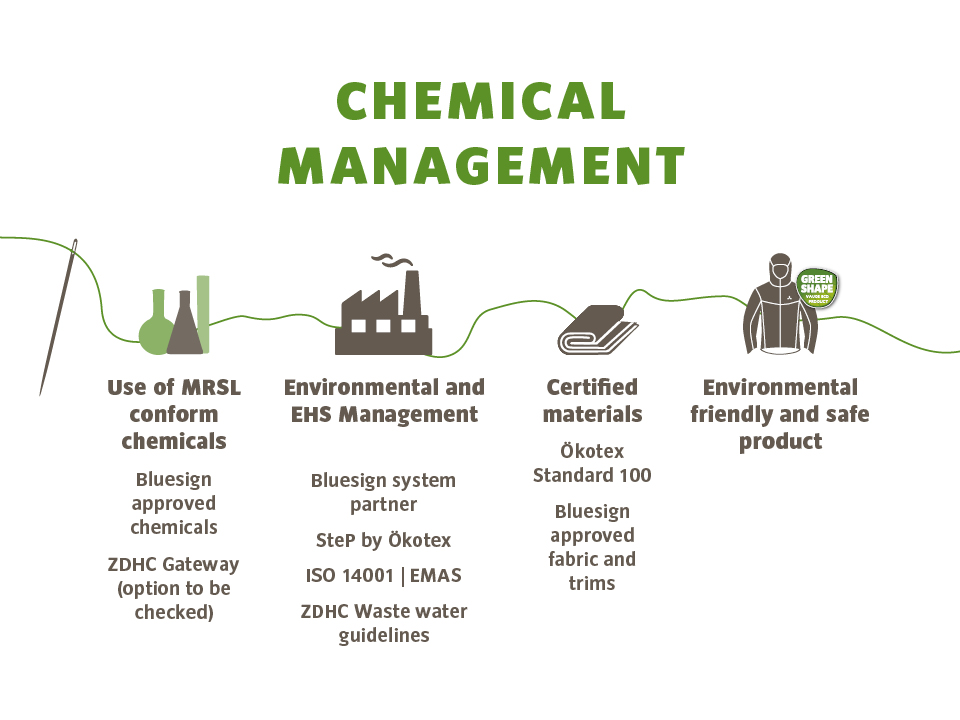

How does a Harmful Materials Management System work?

By consistently using MRSL-compliant chemicals and conforming with a certified Environmental Protection and Occupational Safety Management System in our production facilities, we work exclusively with certified materials that meet the highest sustainability standards. This also means that these materials were produced with little or no risk to the environment or the employees on site. We use these materials in your Green Shape product.

Your guarantee for an environmentally friendly and safe product.

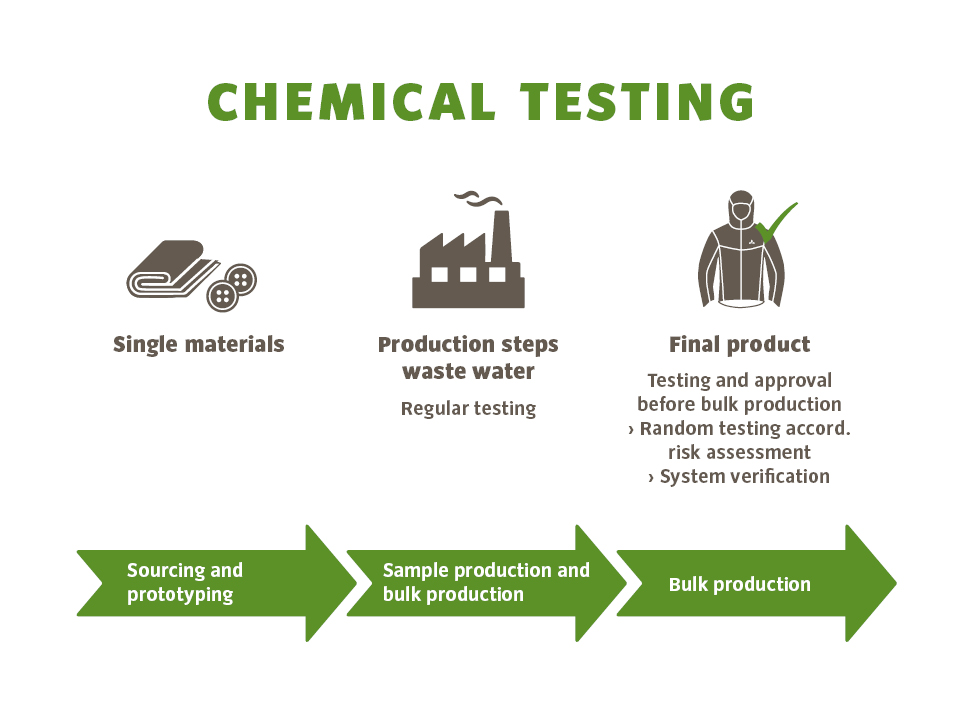

When are tests carried out?

We require or carry out chemical tests on the individual materials and components even before the final selection of materials for the coming season. During the ongoing sample or main production, random wastewater tests are carried out by independent laboratories. Testing of the finished product is only carried out to monitor our upstream testing procedure.

Results of our hazardous substances tests

Our system is working — in 2017 significant improvements were once again visible.

56 random samples of materials and marketable goods were tested

Number of chemical tests, materials and products

Create your own infographicsResults of chemical tests, materials including non-nominated materials

Create your own infographicsResults chemical tests on finished products

Create your own infographicsIn 2017, 56 samples in total were examined. Of these, 38 were tests of materials and 18 were tests of products. This year, one focus was on the materials used for shoe production and the finished Green Shape shoes in our Collection.

All samples met the requirements of REACH. For some material samples, values were found that were higher than allowed in our MRSL. These were primarily local supply, non-nominated materials provided by the producers. These materials are on the way to meeting the VAUDE MRSL.

In the event of such a nonconformity, we immediately enter into discussions with the supplier to achieve intermediate and long term improvements. However, should these tests deviate from legal requirements, the goods must be destroyed in order to prevent them from reaching the market or the end customer.

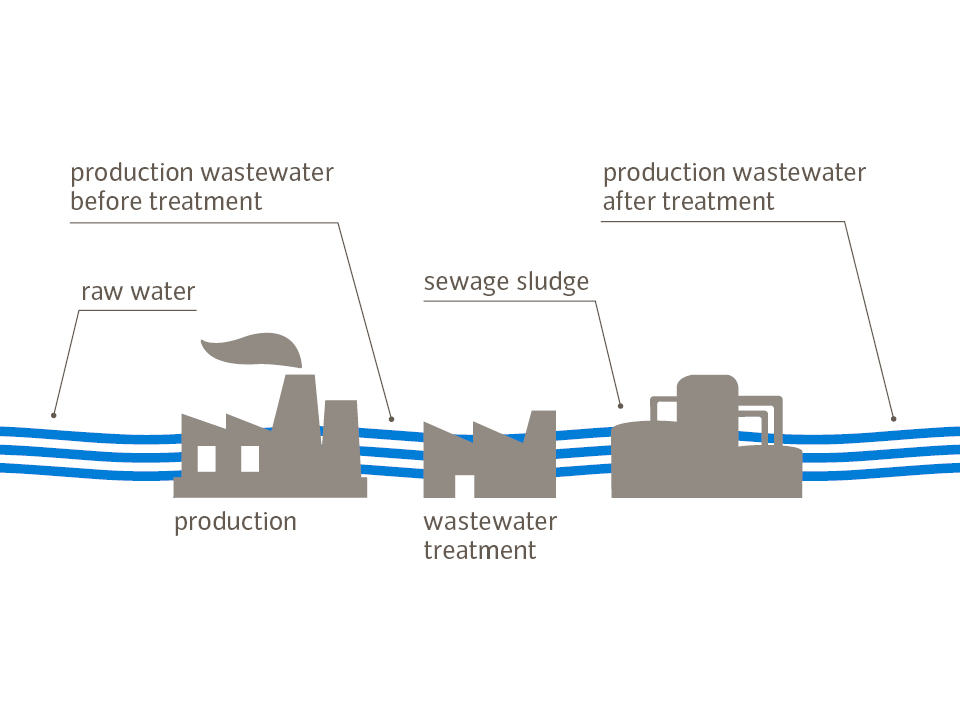

Wastewater tests

Fresh water must be pre-tested to determine whether hazardous chemicals have been used in production (such as for the fabric of a garment) or to ensure that no hazardous substances enter into the facility’s wastewater. Sometimes hazardous substances can already be found here in dangerous concentrations. After obtaining this initial value as a reference point, wastewater tests are carried out before and/or after wastewater treatment. This serves to monitor the quality of the wastewater treatment by the supplier. In addition, sludge is also tested as many substances are absorbed during wastewater treatment.

The Waste Water Guideline developed by ZDHC is currently gaining acceptance in the supply chain. This guide contains clear guidelines and procedures for sampling and chemical testing of wastewater and sludge in textile production. VAUDE bases its wastewater tests on this guideline, as it specifies all relevant points. This also enables closer cooperation with other brands.

Results of Wastewater Tests

Overview of available wastewater tests

Create your own infographicsConsistency with ZDHC specifications

Create your own infographicsFoundational: Minimum requirements, complies with local legal requirements and enables effective monitoring of the use of MRSL-compliant chemicals

Progressive: deep knowledge of chemicals management and includes advanced wastewater treatment process

Aspirational: Exemplary behavior, continuous improvement in chemicals management and Wastewater treatment >> Best in class

Consistency with VAUDE MRSL:

Create your own infographicsSome of our suppliers publish their wastewater test results on public platforms such as IPE, but there are still some who resist using Chinese platforms. The ZDHC Gateway is currently emerging as an alternative platform for the publication of wastewater results. Whether or not this will become a public platform will be decided in 2018. Since many of our suppliers carry out tests in accordance with the ZDHC Waste Water Guidelines, we believe this platform makes sense and are already in discussions with the ZDHC. Until we have clarity here, we will publish the aggregated results here in our Sustainability Report and encourage our supply chain to publish their results at IPE or soon at the ZDHC Gateway.

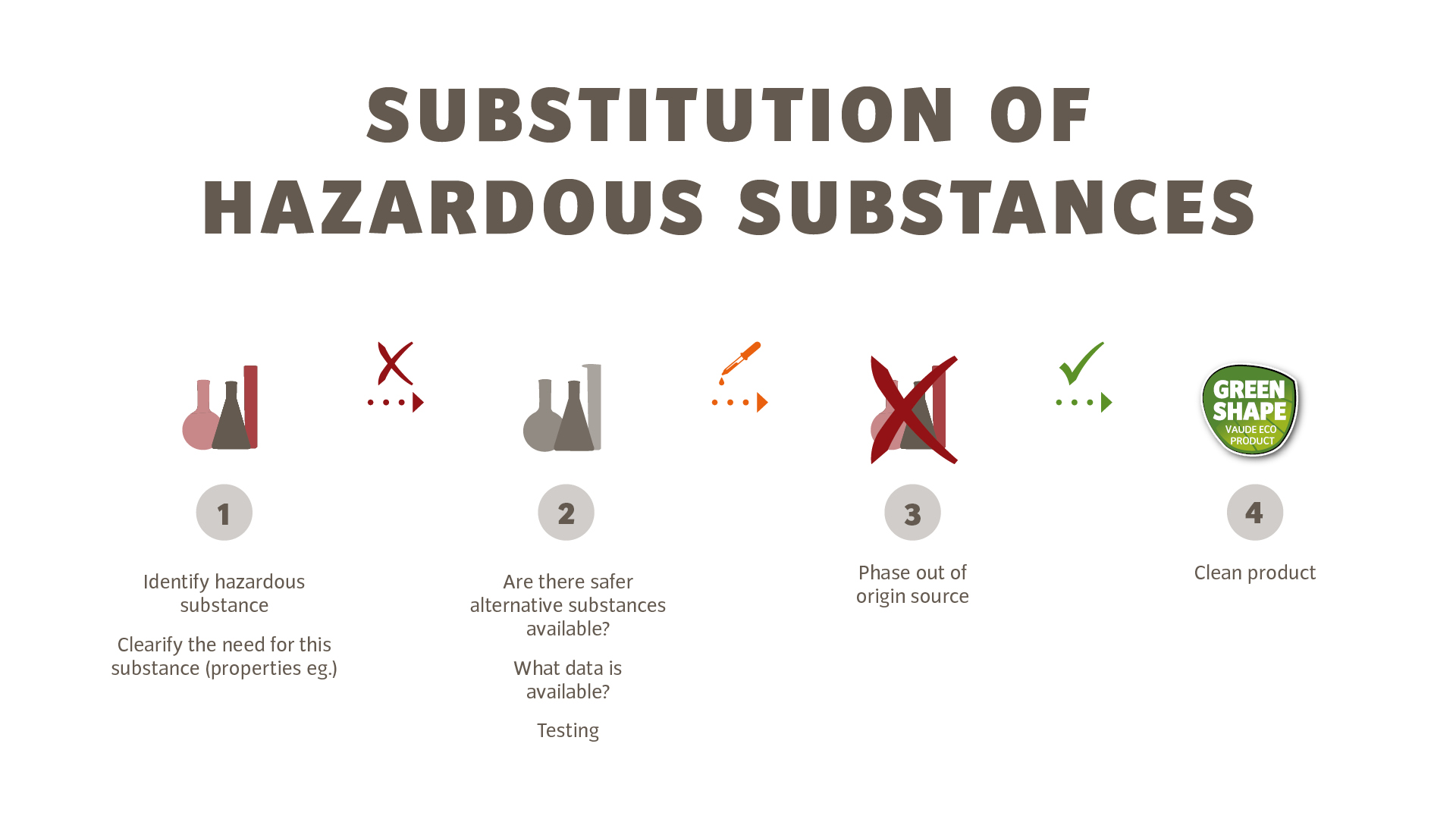

Substitution of hazardous substances

We are working diligently on substituting the following substances with less hazardous alternatives:

- APEOs (eg detergents)

- Azo dyes (synthetic dyes)

- Polycyclic aromatic hydrocarbons

- PFOA (Perfluorooctanoic acid)

- Phthalates (plasticizers)

- PVC

- Solvents

- Organotin compounds

Our systematic approach shows us precise the areas where we need to take action, including which materials and which suppliers are affected, which allows us to work closely with our partners improvements.

Read more.

| GRI: | 103 |