Upcycling – we prevent valuable materials from being thrown away

Upcycled by VAUDE: What happens at our company?

VAUDE Upcycling Workshop

Under the motto “From remnants to raw materials” we have launched a small, exclusive upcycling workshop where we manufacture beautiful, useful products with creative ideas and skilled craftsmanship – each one truly unique!

From pilot project to Upcycling Workshop

Naturally, we also create residual materials. Pure polyethylene and polyamide are transferred to plastics processing for the production of high grade secondary raw materials. However, the majority of the production waste at our Manufaktur ends up in residual waste bins. These are mainly made up of textile off-cuts, scraps and general remnants. Other instances: waste also accrues in our product service department when items are returned that can’t be repaired. In addition, there are old product prototypes and recyclable waste from the kitchen and logistics. Read more about waste.

So, we asked ourselves how we could reuse these residual materials without any loss of value.

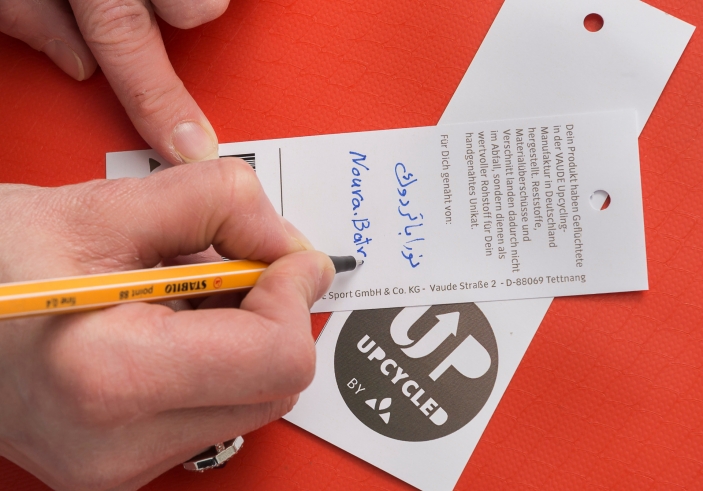

In 2016 we implemented a project to make shopping bags using material remnants from our Manufaktur in six sewing workshops by groups of refugees. We sold the bags at a sale event in the VAUDE store in Ravensburg and in our Metzingen outlet. The proceeds were donated to a joint project with the refugee program, Asylnetzwerk Tettnang. A market check showed that the bags were well received by consumers so we set up an Upcycling Workshop at the end of 2017, creating with two new jobs for refugees to produce the bags.

The Deutsche Bundesstiftung Umwelt (German Federal Environmental Foundation) is supporting the project with €70,000. This is matched by VAUDE with a further €70,000.

The project is set to run until December 2018. After that, we aim for the Upcycling Workshop to break even and continue operations.

|

Überschrift

“By implementing an upcycling production process coupled with the development of a new business model, VAUDE is opening up new opportunities for value creation while at the same time saving resources and reducing waste. The integration of affiliated companies and institutions will also create a platform for upcycling production. |

Read more about our commitment to refugees here.

Shopping bags and repair kits

Leftover fabrics from our Manufaktur production facility are, of course, our most evident residual material. Since 1980, we have been producing backpacks, bike bags and lifestyle bags made of robust, durable materials directly at our company premises in our headquarters in Tettnang, southern Germany. More about it at – “Made in Germany”

Instead of disposing of die-cut remnants and excess fabric that accumulates during production as we have in the past, we now sort and collect all the pieces that are large enough to be used to sew new products. We bring these materials directly to the newly established Upcycling Workshop where they are handcrafted into one-of-a-kind pieces. Based on the shopping bags from our first sewing workshops, we have created two design templates – one larger and one smaller bag – which are now sewn in the Upcycling Workshop.

We estimate the amount of residual waste that we will be saving in 2018 to be around 900 kg. Since January 2018, we have been recording the amount of material that we process in the Upcycling Workshop and will report on this in the future.

Starting in spring 2018, the bags will initially be available in VAUDE Stores and in our factory outlet near Tettnang. Sale promotions with our retailers will follow in November.

Another upcycling product is a small bag that we produce for our cooperation partner iFixit. These bags are filled with practical sewing accessories such as needles, yarn, iron-on patches and tools, and will be sold as repair kits via the iFixit Shop.

Upcycling-bags made from Zeppelin fabric

We will also be producing upcycled shopping bags and backpacks for the Deutsche Zeppelin-Reederei as part of a pilot project – using the outer shell of a decommissioned Zeppelin NT. Instead of disposing with this old shell, beautiful souvenirs will be created so that fans of this famous airship will be able to buy these unique bags and packs from the Zeppelin shop in Friedrichshafen or online in the fan shop.

Upcycling Community

After establishing our Upcycling Workshop, in 2018 we want to go one step further and create an external upcycling community and material exchange together with other companies, schools and creative artists. Our goal is to create a platform that companies can use to make valuable residual materials available for upcycling projects. "Upcyclers" can then use these materials for their products and launch their projects onto the market.

Cool gym bags made from used VAUDE advertising banners that you can buy in VAUDE stores are manufactured in a German sewing facility.

Cool gym bags out of old advertising banners

You can buy cool upcycled gym bags in our VAUDE stores. These are made from used advertising banners in a sewing facility in Germany. In the future we plan to produce them in our Upcycling Workshop.

Find a list of our stores here.

Together with schools, we have been involved in numerous upcycling projects, raising students' awareness and enthusiasm for the issue.

For several years we have worked with students from the Technisches Gymnasium Ravensburg on the development of a sustainable business model within the framework of the project “Umweltprofis von morgen” (Environmental champions of tomorrow). In 2016 and 2017 students came up with ideas for upcycling VAUDE material remnants. Read more here

In 2016, four students used recycled advertising banners and returned products that couldn't be repaired by our service department, and turned them into new bags that could be used as pencil cases or for cosmetics.

In 2017 another group of students designed a headphone case using remnant materials from our Manufaktur.

Roterfaden pocket companion with used tent materials

Used tent materials from VAUDE tents that couldn't be repaired at our Repair Service get a new life as a pocket companion from Roterfaden.

These innovative products are 100% handmade in Germany.

Find the pocket companion with used VAUDE tent materials here

More upcycling projects

|

Costumes for a dance performance made from VAUDE material remnants

A Belgian school made costumes for a dance performance from VAUDE material remnants. |

|

Bags Czech Republic

Bags made from VAUDE material remnants by a Catholic relief organization in Kralup by Moldau, Czech Republic |

|

Leggings Czech Republic

Gaitors made from VAUDE material remnants by a Catholic relief organization in Kralup by Moldau, Czech Republic |

Material remnants from our producers can also be used to make useful items such as curtains for the dressing rooms in our VAUDE stores.

New products from production remnants

Material remnants also accrue in the production facilities that we subcontract to. When we have large amounts of remnants, we can use them to produce special one-off product models. Our producers use smaller leftover quantities for the training of new employees or training purposes. Starting with the Summer 2019 Collection, we will systematically record the leftover quantities per collection.

We also rely on upcycling from leftovers in the outfitting of our VAUDE Stores. For example, the curtains for the changing rooms are made out of leftover Packs 'n Bags materials. The clothes hanger labels for our sale items are also made from remnant materials.

Unfortunately, we still don't have a recycling option for smaller remnant amounts. This generally comes with significant effort and costs (such as those due to customs regulations) when processing them or bringing them to our headquarters. After we have built up our internal structure for upcycling and material exchange, we want to concentrate more intensively on this issue.

Upcycling vs. Downcycling

Currently about 82 % of waste in Germany is recycled*. Recycling waste means that the raw materials and energy are put back into the commercial cycle. The most common form of this recycling is the combustion of waste to produce energy. High quality waste is transformed into a lower quality product.** For this reason such processes are known as downcycling.

There are also more sustainable and more effective ways to re-use this waste than in elaborate downcycling processes. The idea is to create new products from waste that are equivalent or higher in value than the materials used. The transformation of “useless” waste into new items is known as upcycling.

**https://www.nachhaltigkeit.info/artikel/downcycling_2007.htm

| GRI: | 301-2 |

| GRI: | 302-2 |