Synthetics from renewable resources

Forward to nature

VAUDE uses synthetic materials such as polyester, polyamide or polyurethane for many of its products. These materials are derived from petroleum.

We have set ourselves the goal of increasing the amount of renewable raw materials we use. In this way, we can use less fossil fuel-based resources and avoid adding more plastic to the planet.

Animal-based, plant-based, recycled, biobased

Renewable resources can be natural plant fibers such as organic cotton, nettle or hemp. They also include animal-based raw materials such as down, camel hair or merino wool, which are optimal from an ecological point of view. Then there are fibers made from tree cellulose such as regenerated TENCEL®. Read more here

We use as many recycled materials as possible in order to conserve resources. Read more here

Coffee grounds for waterproofing

New in the VAUDE collection is our Ceplex Green membrane, which includes a fabric that incorporates used coffee grounds.

In this innovative membrane, 25 % of the conventional polyurethane is replaced by S.Café®. This high-performance product is made from recycled coffee grounds, so the membrane that’s made from it is partially biobased and made from renewable raw materials. Sound exciting?

Read more here.

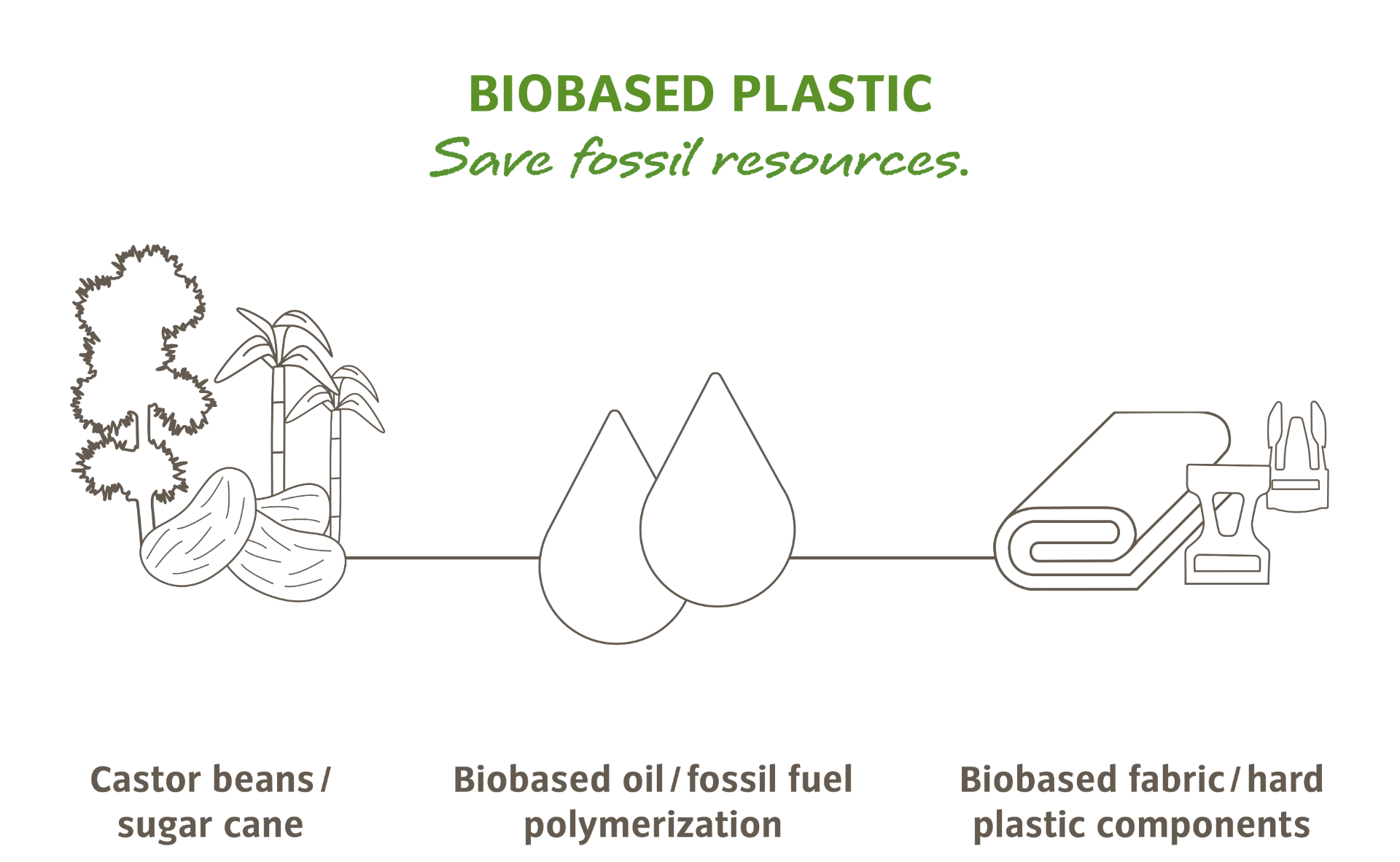

Castor oil for zips

In the Winter 2018 Collection we started using bioplastics for hard plastics and textiles. In our Green Shape Core Collection and Packs ’n Bags series, we use EcoPaXX® for plastic components and fabrics – a polyamide made from 70 % castor oil.

The robust castor plant grows without additional irrigation on barren soils that are unsuitable for growing food. The oil is pressed from the beans of the plant and can be used to produce polyamide fibers as well as plastic parts such as zips and hooks.

Bioplastics for durable products

In some cases, materials made from biobased plastics have even better functional properties than conventional plastics – they weigh less, for example. However, the amount of energy consumed during production processes varies widely and not all bioplastics automatically equate to higher environmental credentials.

Bioplastics that utilize waste from the food industry are ideal; rather than requiring the cultivation of additional crops, residual materials are recycled. A great deal of research and development is still needed before these materials can be used for textiles however.

Because these materials and technologies are still very new, we are staying closely tuned and are looking forward to the innovations they are making possible.

Until that time, we will continue to adhere to the recommendations of our partner, the WWF. We will use bioplastics for durable materials, but not for disposable products such as packaging.

Principles and trade-offs

Clearly renewable resources are a good option. Unfortunately, there are a few pitfalls that need to be avoided.

We think that it is important to avoid any conflict between cultivating agricultural raw materials (such as corn) and the production of food. This is difficult to ensure: At the moment, our decisions are based on the location of the growing region and the living standards of the local population.

In addition, VAUDE Green Shape products are not made with genetically modified materials. To verify this, we require confirmation from our suppliers that they do not use genetically engineered substances.

We in the VAUDE CSR-Team have hotly debated one exception.

Two shoe models in the 2018 Summer Collection include a biobased TPU in the heel counter and toe cap. This innovative material is made from 50 % renewable raw materials and is characterized by a high abrasion resistance and low weight. Currently however, this material is only available in a form that includes a proportion of genetically modified crops.

In this instance, we had to decide which was more important: conserving fossil resources, lowering greenhouse gas emissions, and promoting the use of innovative materials made from renewable resources or excluding all genetic engineering.

For a short transitional period of two seasons, we opted for an exception to our Green Shape exclusion criteria. Thereafter the material must be available in a non genetically modified version or we will discontinue using it.

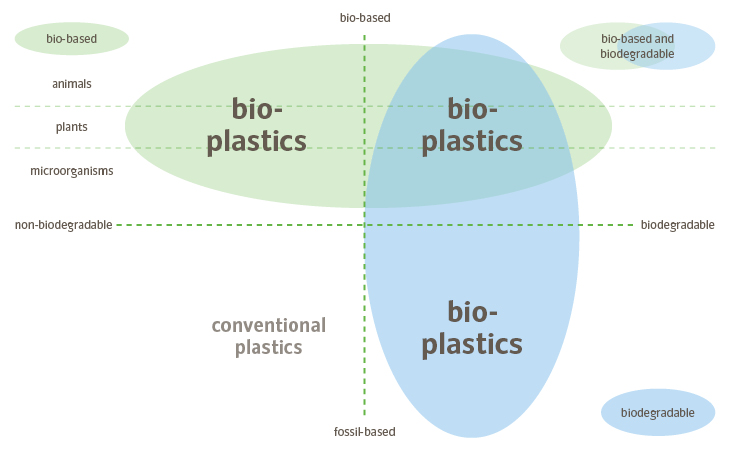

Biobased or biodegradable

Synthetics that are made from renewable resources rather than petroleum are highly innovative. Frequently, these types of bioplastics are equated with “biodegradable” or “compostable” – but this isn’t always the case.

Many biobased synthetics are similar to conventional plastic in that they are virtually non-biodegrable. By the same token, there are also conventional, petroleum-derived plastics that are biodegradable.

The question is whether "biodegradable" actually makes sense from an environmental perspective. On one hand for example, you would think that it would be great if plastic would just dissolve in the ocean.

On the other hand, the production of plastics – whether derived from petroleum or from renewable raw materials – requires significant energy. The result is a high quality material with many functional properties. Doesn’t it make much more sense to reuse or recycle such materials rather than leaving them to degrade into “nothing” (CO2 and water)?

We are following the current scientific discussion on this issue with interest. Read here to find out what Germany’s Federal Environment Agency has to say about bioplastics:

| GRI: | 301-1 |