Detox – a challenging path to freedom from pollutants

»When Greenpeace set its sights on the outdoor industry in 2012 with its Detox Campaign, we saw a great opportunity to finally make a difference across the industry and develop alternatives for chemicals of concern. As a single mid-sized brand, we hadn’t had enough influence with the material manufacturers before that time.«

The focus of Greenpeace's demands was to eliminate the use of polyfluorinated and perfluorinated chemicals, known as fluorocarbons or PFCs for short. These are used to produce membranes that are integrated between layers of fabric to prevent water from penetrating, while at the same time remaining breathable. They are also applied to the outer surface of rain gear to provide durable water repellency. The water-beading effect is what makes a rain jacket effective.

By voluntarily signing the Greenpeace Detox Commitment in 2015, we made a clear commitment to phasing out the use of chemicals of concern by 2020. We knew that this would be a huge challenge. In addition to PFCs, there were ten other critical substance groups that couldn't be used or released into the environment. Furthermore, the voluntary commitment included an active contribution to a responsible business model focused on more sustainable consumption and transparent reporting on progress and challenges.

»VAUDE takes its corporate obligations seriously and is a living example of the fact that transparency and the regulation of global supply chains is possible. The company is showing the rest of the outdoor sector how to move towards a sustainable recycling economy. The substitution of hazardous chemicals is at the forefront and the company has initiatives for ecological design, durability, rental and repair to extend the life of their products.«

© Foto: Jiri Rezac/Greenpeace

What has changed in the last 5 years?

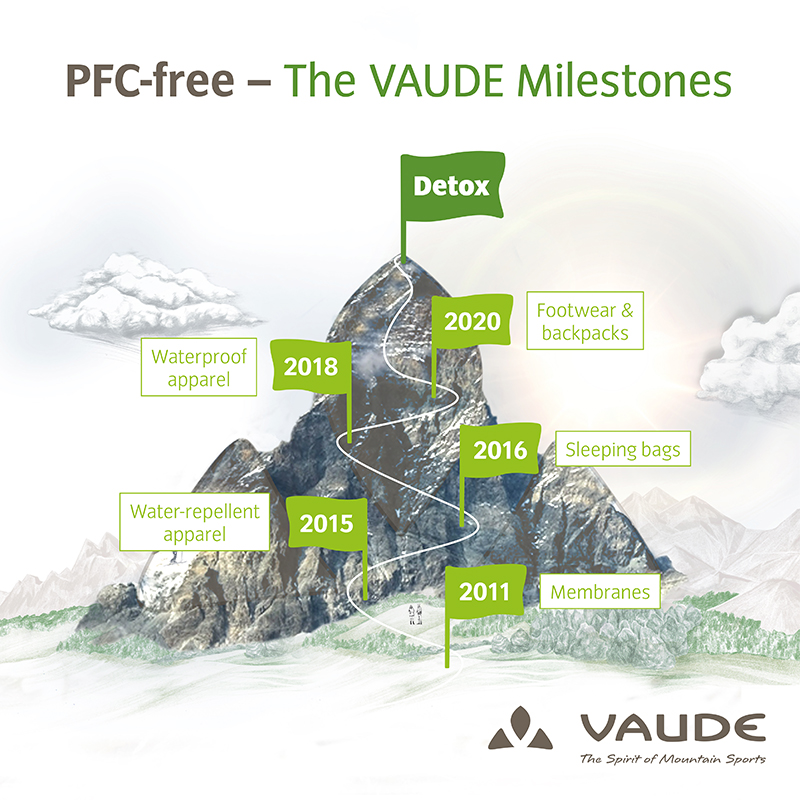

VAUDE hasn't used PFCs in membranes since 2011. When it came to fluorocarbons, the biggest challenge for us was to provide our outer fabrics for weatherproof apparel with a PFC-free finish that offered durable and reliable water-repellent functional properties. Public pressure from the Greenpeace campaign provided the push the textile industry and chemical supply industry needed.

»We worked closely with our producers and suppliers, organized round table discussions and brought together partners who were used to acting as competitors. It was successful. Promising new developments came to the market which led to testing, testing, and more testing.«

Each material reacts differently depending on its surface textures or colors, and process reliability had to be established in production. Several hundred material tests with the new PFC-free alternatives were necessary to get from laboratory tests to practical application.

The entire VAUDE apparel collection has been PFC-free since 2018. Unfortunately, we had to fall back on a PFC-containing finish for two styles of weatherproof jackets and weatherproof pants in the current Winter Collection 2020, as acceptable water-repellent properties could not be achieved with PFC-free alternatives. This was a setback that shows just how complex and challenging the transition to pollutant-free chemicals continues to be. We were all the more pleased that we managed to ensure full functionality again starting in 2021 with our PFC-free Eco Finish. In both the Summer 2021 and Winter 2021/22 Collections, all our apparel products will again be 100 % PFC-free.

Post-waterproofing is necessary

It is important to note that eco-friendly, fluorocarbon-free DWR is often not (yet) as durable as conventional PFC-containing versions. However, functionality can be permanently maintained by regular re-waterproofing after washing. This should be carried out with an eco-friendly, solvent-free and fluorocarbon-free waterproofing agent. We educate our customers about this issue, actively providing tips for eco-friendly care and maintenance and also offer professional waterproofing services.

Additional information about water repellent materials and impregnation

We have eliminated 7 of 11 substance groups. We have not fully eliminated 4 substance groups.

In the field of chemical substitutions, PFCs are only one of 11 substance groups that we are focusing on. We have already completely eliminated 7 substance groups. For the remaining 4 groups we are working full steam to find substitutions and are confident that this will be achieved. It is still our declared goal to find alternatives with which we can completely replace chemicals of concern. To ensure compliance with our limits and regulations, we are working with the Manufacturing Restricted Substances List (MRSL). This is a list of substances that are either completely prohibited or restricted by limit values and it applies to the entire manufacturing process. It is therefore not just a matter of obtaining a pollutant-free end product, but of taking all stages of the manufacturing process into account, from yarn production, weaving, dyeing, coating/laminating to finishing, such as for a water-repellent water beading effect on outer fabrics of the finished product.

»100 % of our primary partners have signed our MRSL and committed themselves to compliance with our requirements, which is verified by periodical wastewater tests.«

Future-oriented ideas and business models for sustainable consumption

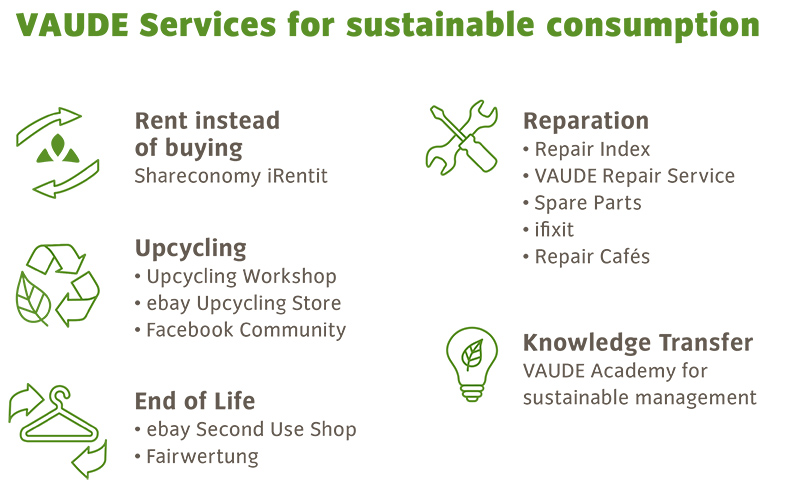

By signing the Detox Commitment, we have not only committed ourselves to eliminated the use of harmful chemicals, but also to developing an active contribution to new, responsible business models with environmentally friendly products for more sustainable consumption. We have initiated many measures and new business models to keep the ecological footprint in the life cycle of our products as small as possible. For example, we have now launched the eBay Upcycling Store – a materials exchange for creative people. Residual materials that accumulate in our manufactory are auctioned off there for a good cause. The platform is open to interested companies from the textile industry and we would also like to motivate them to offer their valuable material residues via the platform instead of disposing of them. Since 2017, we have also been offering iRentit, a shared economy platform that allows users to rent and share our products.

To keep the ecological footprint of our products as small as possible, we are committed to ensuring that they can be used for years to come. To this end, we have, for example, firmly anchored the issue of reparability in the design process via a rating system. We also make replacement parts available and provide practical tips on the maintenance and repair of products. We have an in-house Repair Workshop and cooperate with repair services such as iFixit or various Repair Cafés. In addition, since May 2020 we have been sharing our experience and expertise in sustainable entrepreneurship with interested companies, organizations and educational institutions through the "VAUDE Academy for Sustainable Business."

More about our sustainable projects & services:

Tips for a long product lifespan – Forever Yours

Ebay Upcycling Store

iRentit Service

VAUDE Repair Index

VAUDE Academy for Sustainable Management