Supply chain management – supportive and ambitious

Environmental friendliness, fair working conditions and high quality throughout the supply chain

The supply of our products is complex, international, and presents many ecological and social challenges.

It is quite right that you should expect us to assume responsibility for the conditions under which your VAUDE product is manufactured. And this also goes for ecological and social issues, from the raw material to the production of the fibers, yarns and fabrics to the finished product.

VAUDE – a pioneer in fair working conditions

We view it as our responsibility to push these themes in countries where levels of awareness are still relatively low.

VAUDE has already been a pioneer in the implementation of fair working conditions with our production partners, as well as in the reduction of environmentally harmful substances used by our materials suppliers and in fulfilling our high standards in quality.

Another step further in the supply chain

Now we are taking it a step further and are committed to fair working conditions, environmental friendliness and quality throughout our entire supply chain – from manufacturers and suppliers of materials alike. By taking this stance, we are setting ourselves a huge challenge and looking to renew our role as a pioneer.

This comes with major challenges for us. But it is also part of our holistic, sustainable approach: We want to accept responsibility for our entire supply chain.

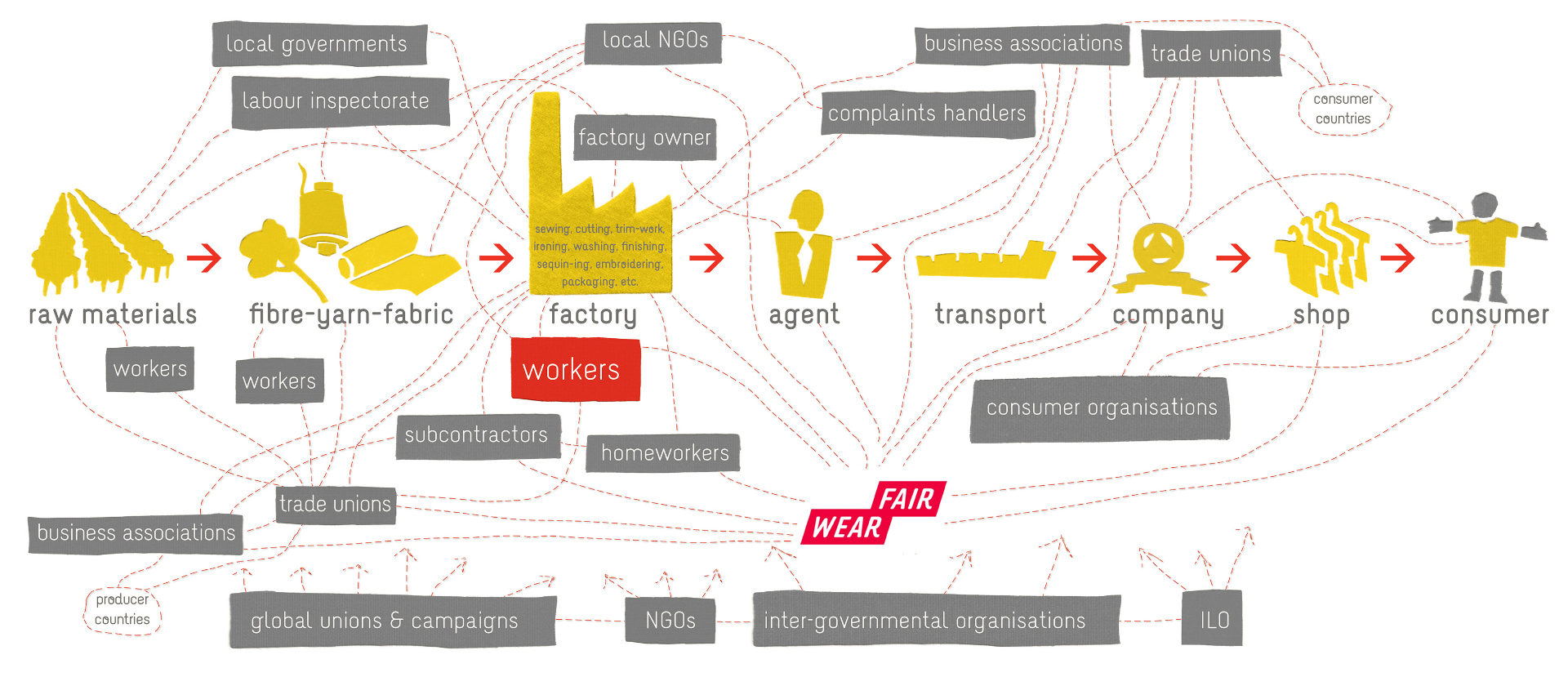

Graphic: Fair Wear Foundation

Clothing manufacturers: cut – make - trim

Our direct business partners for product manufacturing are our producers. They prepare the fabrics, cut out pattern pieces and sew them into finished products. Quality control and packaging finish off the process.

In general, the textile and clothing industry is very labor intensive. The manufacturing of our VAUDE products is very demanding. It requires many people working on many sewing machines – and naturally we need to ensure fair working conditions for them. Read more here to find out how we put this into practice.

Materials – Performance meets Ecology

Most of our materials are bought by our manufacturers in accordance with our specifications for quality, color, quantity, and from material manufacturers that we have already carefully vetted (selected). So, in addition to knowing all of our producers, we also know all of our material suppliers. Find out more

Dialog with these material suppliers whose substances and ingredients we nominate is ongoing and extensive, because they have a big influence on the sustainability of our products. We have worked together with many of them for years and have developed new materials specifically for VAUDE.

Sometimes, our producers use local suppliers for small parts. We now know all of these suppliers and have incorporated them into our monitoring process for hazardous substances; we provide training on how to deal with chemicals and regularly analyze their chemical testing. With coordinated efforts between quality management, purchasing and our team, we are implementing measures that help suppliers achieve constant improvement.

Corruption in the supply chain

As part of our risk analysis program, we address the issue of corruption in the supply chain at a national level using amfori's assessments. This gives us an initial overview of the potential corruption risks in our European and Asian countries of production. Our goal is to delve deeper into the issue in order to be able to take effective and measurable action in the long term.

First steps: RASUM practice-based project

»Businesses that deliberately take responsibility for all of their economic activities are an important pillar for promoting global economic, social and technological progress in harmony with nature.«

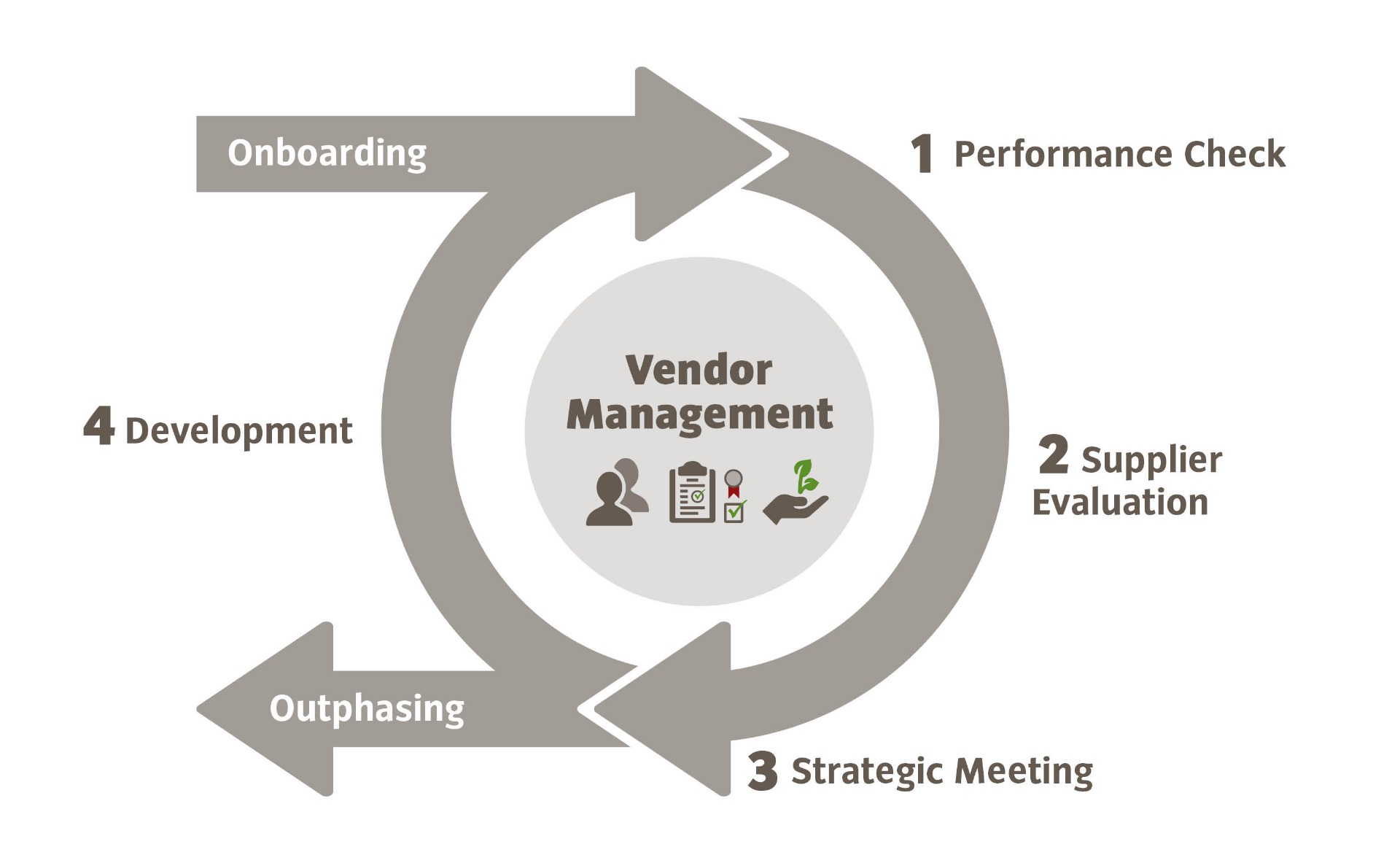

VAUDE Vendor Management

VAUDE Vendor Management is a comprehensive system which we use to guide and support our partners throughout the entire business relationship. The business relationship is divided up into 6 phases: Selection process, vetting, supplier assessment, strategy meeting, development and termination.

Selection process

We have developed a strict system for the assessment of potential partners. Our local experts inspect their production sites by using detailed checklists divided into three areas: Social standards, environmental management and quality. In addition, we sit down for intensive talks with the management team to see whether their working methods are compatible with our approach and whether we can work together.

Then, we decide whether the new partner is or isn’t a good fit for us.

All our partners must sign an agreement to comply with our requirements and agree to work together with us on continuous improvements.

1. Performance Check

VAUDE has trained its local teams of experts so that they can check the performance of our partners with regard to our sustainability criteria. We have developed a special tool for the purpose that covers both international standards and local laws. Sewing manufacturing sites come under the FW Scope and are audited regularly by FW.

The following aspects are checked during inspections:

- Social standards (compliance with the FW Code of Labor Practices)

Environment (Chemicals management, emissions, wastewater)

- Quality

If the production facility has already been audited or certified by another standard (such as FW, bluesign®, ZDHC) the scope of our controls is reduced and we make use of existing data and standards. Our aim is to use our own resources and our partner’s resources in an efficient a way as possible, to positively influence the supply chain.

During the on-site screening, we carry out inspections of the entire production facility. We also check documents and conduct interviews with employees and management.

After the inspection, we work together to draw up a binding corrective action plan that clearly lists any discrepancies.

The VAUDE experts support the new partner throughout the whole improvement process with their vast experience.

Progress of the corrective action plan is also monitored at regular intervals.

In 2018, we conducted the first performance checks and reviewed 8 suppliers in the second and third stages of our supply chain. In 2019, 7 second-tier and third-tier suppliers were evaluated. In 2020 and 2021, we did not perform any further performance checks due to the pandemic. In total, we have therefore already audited 15 suppliers. These cover about 60 % of our material consumption. Our local teams monitored the operations and have since supported the implementation of the improvement measures. In addition, VAUDE offers various empowerment measures for all partners.

The experience gained so far has been extremely valuable to us. It is helping us to identify the most urgent challenges and to align the support of our partners accordingly, so that we can work together to improve working conditions over the long term.

2. Supplier Evaluation

At the end of the financial year, we evaluate all our partners throughout all areas of our work together. The evaluation is based on objective analysis of our ERP system and the evaluation of the departments involved.

3. Strategic Meeting

We regularly hold talks with our partners, where the results of the assessments are discussed and necessary improvement measures are decided upon. In additions, long-term goals and growth objective are determined.

4. Development

Evaluating our partners allows us to see in which areas support is still needed.

VAUDE supports development in the supply chain on issues such as detox, science based targets and social dialogue. This is accomplished by means of targeted training from our experts on site or the VAUDE Vendor Clubs.

Various empowerment measures for our partners

VAUDE Vendor Meeting

In 2018 and 2019 we invited all partners in our supply chain to the VAUDE Vendor Meeting at our headquarters.

The VAUDE Vendor Meeting is a strategic assembly in which we inform our supply chain about current developments, our strategic goals and upcoming issues as well as discuss with them how we can implement these goals and turn challenges into opportunities.

VAUDE Vendor Club

The VAUDE Vendor Club is a platform for the exchange of best practices, expert lectures and workshops on a wide variety of issues. This format was developed as part of our "Environmental Stewardship in the Textile Supply Chain" project. The goal is to enable the supply chain to achieve our environmental and social goals. To this end, we are working together with the experts who are responsible for operations in the supply chain on issues such as detox, science based targets or social issues such as fair wages, social dialogue, etc.

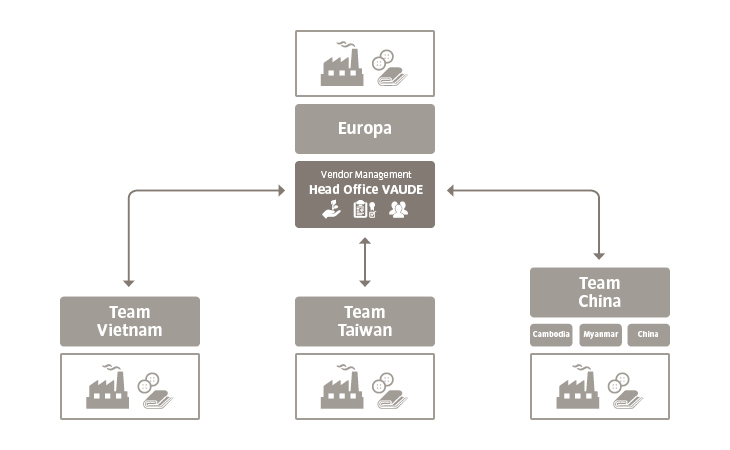

Vendor Clubs were held in Vietnam and Taiwan in 2019.

Many of our sewing factories are in Vietnam, so the focus here was on social dialogue and the introduction of an energy management system as preparation for our science based targets.

The majority of our fabric suppliers are located in Taiwan so the focus here was on Circular Textiles (recycling management in the textile sector) and science based targets. In 2021, a digital Vendor Club was held for our Asian and European partners. In this context, we informed our partners about news in the VAUDE sustainability strategy, the Science Based Targets, Green Shape 3.0 and the Brand Material Goals, as well as about ZDHC and HIGG issues.

Outphasing

There are various reasons why a business relationship might be terminated. If the relationship is dissolved from our side, then we give our producers ample notice and work out an exit strategy together, reducing the quantities we order in stages. This helps our partner to properly prepare for the end of the business relationship and gives them the opportunity to look for new clients.

The three pillars of Vendor Management

Environmental Management

Environmental protection is very important at VAUDE. Manufacturers for and suppliers to VAUDE are obliged to uphold environmental standards through our MRSL and contracts. In collaborative partnerships we work together to make production more efficient and thus reduce the environmental impact.

Social responsibility

Social responsibility has a high priority at VAUDE. We are not only committed to our employees at our headquarters in Tettnang-Obereisenbach, but are also committed to good working conditions for all people involved in the manufacture of our products worldwide.

Quality management

Quality is a matter of course for us. But this cannot be achieved without effort. Our teams throughout the world work closely together with the product development and quality management teams and of course with our manufacturers and suppliers, to ensure a high level of quality.

Mutual collaboration

VAUDE believes in sustainable, collaborative, lengthy and partner-based business relationships.

To us, sustainability is like a team sport. That is why we give our partners rigorous support with implementing our requirements in the supply chain.

Team Vendor Management

Thanks to our local team of experts, we always have up-to-date information on our production facilities. Our partners can turn to them any time for advice and assistance, and they help ensure that conditions throughout our supply chain are steadily improving.

| GRI: | 102-9 |

| GRI: | 102-10 |

| GRI: | 308-1 |

| GRI: | 308-2 |