Textile production requires large amounts of water

Water consumption in all process steps

Water is required in almost all process steps of textile production:

- the cultivation of agricultural crops such as cotton

- the rearing of animals whose wool or feathers is used such as sheep and geese

- the production of synthetic fibers such as polyester

- in all washing, dyeing and finishing processes

The WWF assumes that the textile industry consumes 13.6 liters of water for every euro of turnover. 43% of this is accounted for by wet processes such as washing, dyeing and finishing of textiles.

High risk for global water scarcity

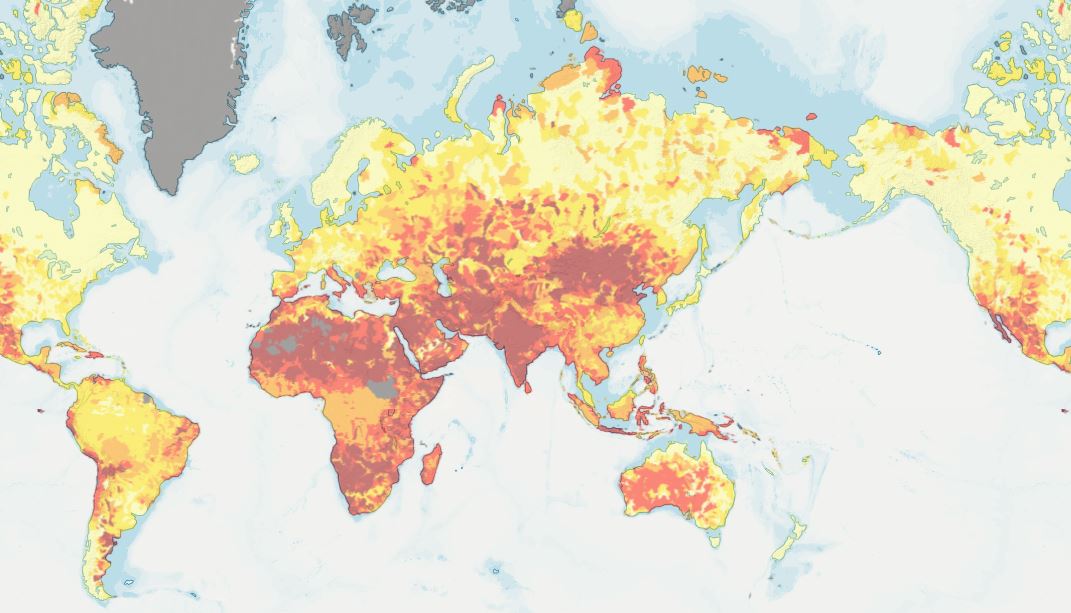

The World Resources Institute highlights the global risk of water scarcity. In the Water Risk Atlas (see graphic below), the extent of this threat becomes clear. The red areas in the 2019 chart show where there is a high to very high risk of water scarcity. What can be seen here is the baseline view which represents the current situation. It depicts water trends that are expected based on historical data. The tool does not display real-time data.

Water management in the supply chain

In a pilot project VAUDE has conducted an Environmental Stewardship training course with a number of its suppliers. As a result, more than 5,000 cubic meters of fresh water are saved in production every year. Read more here.

Most of our fabric suppliers work in accordance with the bluesign® system. For VAUDE, this is an important component of the entire environmental stewardship system.

Nevertheless, we often do not know the hard figures for our suppliers’ water consumption. One reason for this is that we are often only one of many of their customers. Another reason is that a uniform method for measuring the water consumption of an outdoor product is still lacking.

This gap will hopefully be closed by the HIGG Index – an international database to evaluate the sustainability of your outdoor trousers, jackets, etc. in the future. Read more here

Great potential for savings

In addition to a focus on the careful use of water in production, we are also working with our suppliers to process more and more substances that have been produced using particularly water-saving technologies. This includes more eco-friendly dyeing technologies: For example, modern dyeing machines save up to 30 % water and 70 % chemicals compared to older designs. More about this here.

For VAUDE, water management in the supply chain is a high priority issue for the coming years. That is why we launched the "Water Stewardship" project this year. In the first step, we will analyze our own supply chain to identify the risks and then develop and implement effective measures for improvement. To do this, we are following the WWF guidelines for water management. We will identify the manufacturing steps in which water consumption is particularly high and what opportunities there are for improvement through process optimization and new technologies. We will also assess current and future water availability in our countries of production using the WWF Water Risk Filter and incorporate this into our strategic decisions. There will be more on this in our next report.

| GRI: | 303-1 |

| GRI: | 303-2 |

| GRI: | 303-3 |

| GRI: | 103 |