Goal: Reducing Residual Waste

“Rubbish” or raw materials?

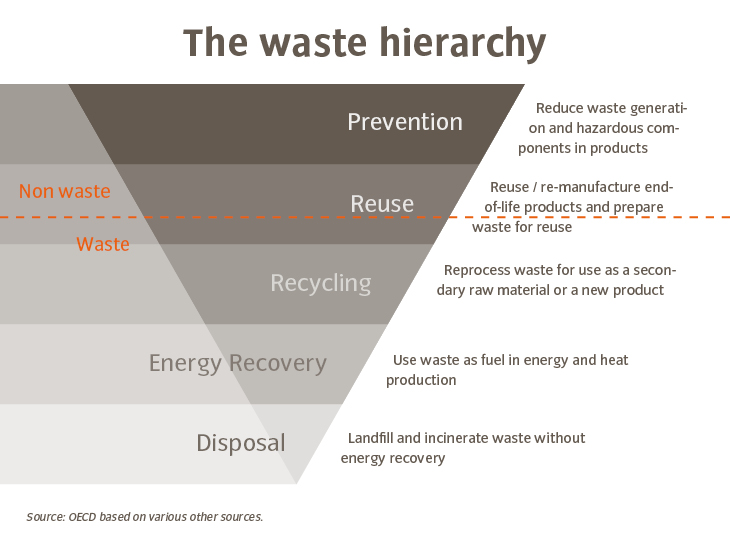

"Rubbish" is a key environmental issue. For one, it means that limited resources are wasted. For another, some types of waste (such as plastic bags or synthetic microparticles that end up in the oceans) pose a serious threat to wildlife. Read more about it here.

Last but not least, hazardous substances can be released into the environment if waste is not disposed of properly.

Avoiding waste as far as possible

Despite the fact that waste management is already very well regulated in Germany, it is still an important environmental issue.

All waste is collected by local waste management companies and properly disposed of, or it is brought to a collection station by VAUDE employees with documented proof.

Waste at VAUDE

Create your own infographicsResidual waste continues to be our "problem child"

At VAUDE, residual waste is primarily generated in our Manufaktur production facility and includes textile remnants from die-cutting or, at times, semi-finished products that have not passed our strict quality control. Much of this ends up in our upcycling program (more about this here), the rest goes into the residual waste system. This year we also had 160 kilograms of waste from our own Corona test station that had to be disposed of as "hazardous waste".

Waste from marketing events for which sorting would be too complex as well as products from our repair service that can no longer be repaired and cannot be used as a second hand products are also disposed of as residual waste. The criteria we use to sort such products are taken directly from the non-profit organization FairWertung, where we donate all products that can still be used. More about this here.

Thermal Recycling

It's true that our residual waste volumes have been continuing to decline since 2016 following the completion of intensive construction measures in 2014 and 2015 (more on the conversion here). This year, the total volume of residual waste decreased by 1%, although slightly more residual waste was produced in Administration & Sales.

Nevertheless, we still have far too much residual waste that is not recycled but "thermally recovered" – incinerated as fuel for energy-intensive industries such as cement production or energy generation.

This is better than not using residual waste at all, but of course, it would be much better from an ecological standpoint if we reduced our residual waste as much as possible.

This is why we are trying to scale down material remnants in the manufactory by optimizing cutting processes. And we are looking for industrial partners who can use coated plastics for recycling despite the relatively small quantity - so far without success. There are two issues here – our quantities are quite small on an industrial scale and TPU-coated polyester materials are not homogeneous and therefore a real challenge for recyclers.

As part of the ReWerk project, we are collaborating with partners from the fields of science and industry on solutions that will enable the recycling and reuse of our material remnants from VAUDE products with innovative mechanical recycling processes.

Residual Waste (t)

Create your own infographicsUpcycling: Environmental protection with social benefits

Under the motto "From residual material to raw material" we have founded a small, exclusive Upcycling Workshop in which we produce beautiful and useful products with creative ideas and craftsmanship – each one truly unique! A positive side effect is that the project has also created jobs for refugees. Read more about it here.

Waste compared to company growth

Unfortunately, waste often grows with the growth of a company. After years of reducing our waste volumes, 2021 once again saw an increase in the generation of waste materials. The total amount of waste in 2021 was 8 percent higher than in 2011, but we did manage to reduce the proportion of residual waste by 11 percent, even though sales increased by over 80 percent in the same period. This is called "decoupling" resource consumption from growth. Find out more here.

Compared with the previous year (2020) however, the volumes of total waste as well as residual waste have actually increased significantly more than sales (32% more total waste; 23% more residual waste; 17% more sales). This is of course negative from an environmental perspective, even if it can be justified. VAUDE had significantly more employees in 2021, and the VAUDE Manufactory operated multiple shifts for the first time, producing 19% more goods.

Waste in relation to sales growth

Create your own infographicsTrainee challenge against residual waste

Because we know that our percentage of residual waste is too high, our VAUDE trainees are now starting a “residual waste challenge”. Together with the department heads of Manufacturing, Logistics, Maintenance and Marketing and the VAUDE CSR Team as well as the help of an external waste consultant, they are investigating the sources of residual waste, developing a package of measures to counteract the problem and working on a campaign to raise awareness and train employees. We are looking forward to the results and will continue to report on them here.

And what other problems we have with packaging, here.

| GRI: | 306-1 |

| GRI: | 306-2 |

| GRI: | 306-3 |

| GRI: | 306-4 |

| GRI: | 306-5 |