Fair price-performance ratio for our products

What costs and profits are included in the VAUDE sales price?

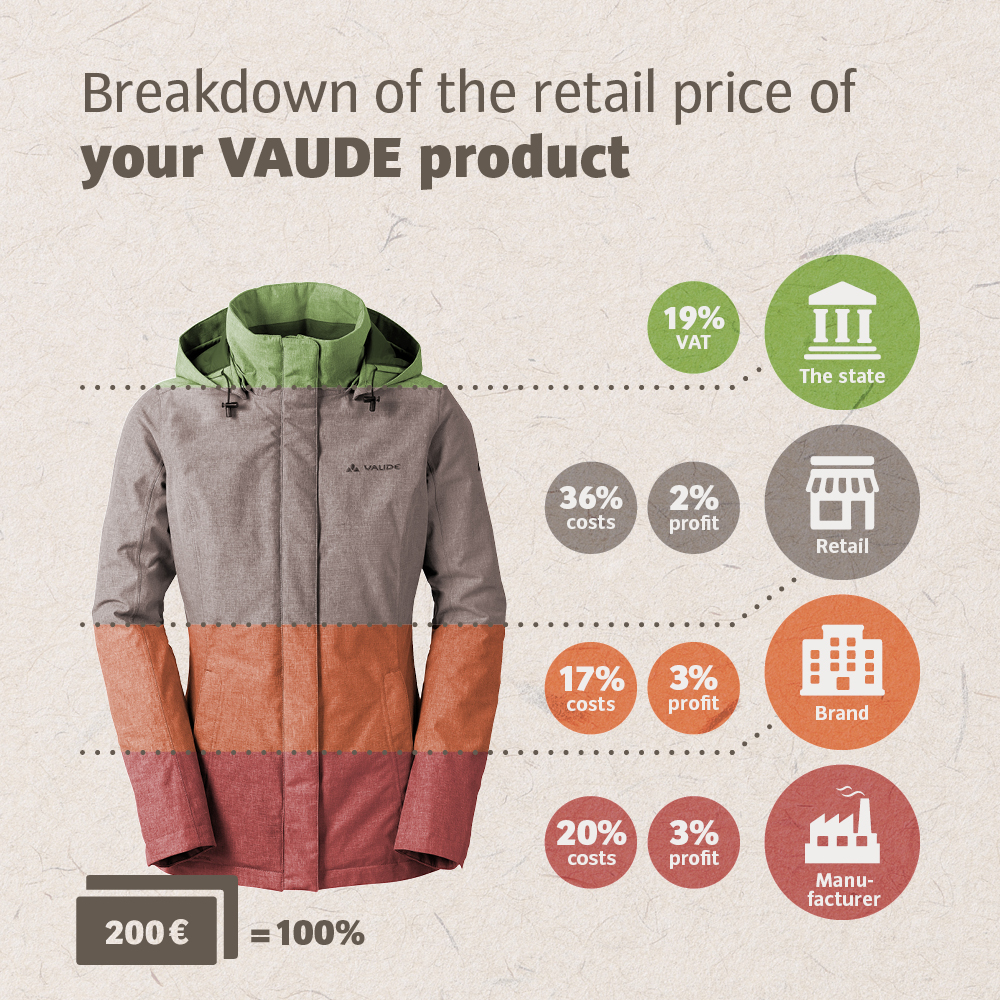

Let's assume you buy a VAUDE jacket for 200 € in Germany. What are the costs involved and how much does each party (the producer, the VAUDE brand, the retailer and last but not least, the state via taxes) earn?

State

Retail

Brand

Producer

A fair price-performance ratio – what does it mean?

Clearly, it’s primarily about the price you as a consumer pay for a product. You can make judgements based on this price – is it high or low, good or bad, fair or unfair? In order to make an assessment, the price has to be considered in relation to another value – the performance that the product offers. In our example of an outdoor jacket, this would include benefits such as protection from wind and rain, the quality of the materials used, the durability of the jacket and, of course, the design and other special features of the product. In addition to functionality, quality and design, there are also more "invisible" benefits such as sustainability and partnership, i.e. ecological and social responsibility along the entire supply chain. All these achievements should now be in a fair relation to the price you pay and here is where it gets complicated.

The price alone says little about the trade-offs. Discount prices are often based on exploitation of the people who make the products, are at the expense of the environment or reflect inferior quality. In other words, not all true costs are reflected in the price. Unfortunately, a comparatively high price is no guarantee for sustainability and quality either. In order to be able to judge whether price and performance are balanced and whether the true costs are reflected, more transparent information about manufacturing processes is needed.

What are the true costs and who bears them?

One example: The PVC-free primary material used in our Made in Germany panniers is up to 80 % more expensive than a standard PVC-containing material that is controversial because of the plasticizers it includes. For the planned transition of our softshell jackets to recycled polyester made from recycled PET bottles, we expect a material procurement surcharge of approximately 10 % compared to newly produced polyester.

Other additional expenses are incurred for complex chemical management systems and environmental certificates that reflect resource conservation and the greatest possible freedom from hazardous substances in material production and production processes. In addition, there are costs for environmental management training and, of course, for fair wages paid in production plants – compliance with which must be regularly monitored. We also have additional costs for a wide range of measures relating to sustainable products in R&D, for our strong commitment to a good work-life balance (we offer a wide range of part-time work models and childcare) and for our commitment to healthy employees (we support them with sports activities and our organic canteen, for example). And last but not least, we have additional expenses for climate compensation payments for unavoidable emissions at our headquarters in Germany.

Of the total additional costs incurred for these measures, only a small proportion can be passed on, as the willingness for retailers to charge higher prices in stores and to consumers has its limits. We sometimes deliberately forego profits here. We can only do this by avoiding expenditures in other areas such as by foregoing expensive advertising marketing measures or by not paying out large profit distributions to external shareholders, as we are a family-run company.

Companies that neglect these sustainability aspects save considerable costs. However, these don’t just disappear; they are merely externalized and passed on to others. If rivers are contaminated with chemicals from textile dyes because there are no sewage systems in place or if companies forego occupational health and safety measures or social benefits, it is ruthlessly accepted that nature will be destroyed and that workers will have to lead a life that’s inhumane. The real costs are therefore not borne by the companies that have commissioned these production facilities and are causing the damage. This form of cost reduction is at the expense of nature and the people in the production process. The price and the true costs of restoring destroyed ecosystems and habitats later or helping people who have fallen ill as a result are then paid by uninvolved parties, the general public and future generations.

Together, even greater performance levels would be possible – but only with higher prices

When pricing our products, we are guided by market prices. There are, for example, key price points, such as €100 hiking pants or our example rain jacket for €200. Our customers compare our products with other suppliers in this price category, so price increases are a sensitive issue. Sustainability criteria are considered good and important by many people and are increasingly coming into focus when shopping. For example, according to the Allensbach Market and Advertising Media Analysis (AWA 2019), the proportion of Germans who are prepared to pay more for environmentally friendly products has risen from 19 % to over 23 % in the last five years. Nevertheless, we have learned from experience – when it comes to the actual purchasing decision in the process of buying outdoor products, price is still often the decisive factor.

»Many people want to consume with a clear conscience. When it comes to actual purchasing decisions, however, price is still often the deciding factor; after all, you can't tell how most products were made. We want to offer our customers transparency regarding our manufacturing criteria and promote responsible purchasing behavior.«

What would an ideal, sustainable product have to cost?

Let's assume that we would make a true VAUDE classic, our Farley hiking pants, even more sustainable than they already are. The pants already bear our Green Shape label and the Grüner Knopf. They are currently made from bluesign® certified polyamide, a synthetic fiber based on petroleum. The bluesign® standard allows only certified chemicals in the manufacturing process. In addition, maximum resource and energy efficiency is taken into account – it is currently the most stringent textile standard we have. In addition, the pants are finished with Eco Finish – no harmful PFC, so they’re environmentally friendly and water-repellent. Like all our producers, the Vietnamese producer of these pants is audited by Fair Wear. But even so, we could make them even more sustainable!

We have set ourselves the goal of converting the majority of our products to recycled or biobased materials by 2024 in order to conserve valuable resources and reduce CO2 emissions to help achieve the 1.5 degree target from the Paris Climate Convention. We could therefore replace the current polyamide fabric with a predominantly biobased fabric made from castor oil. In addition, we could replace the zippers with the best sustainable zippers currently available that include recycled materials. These two measures would increase the current procurement price by approximately 30 %. If we were to pass on this price increase 1:1 with the selling price, the price of the pants would rise from the current €100 to €130. This is a price increase that we are currently unable to implement, either with our retailers or with our consumers. Due to global demands and political decisions for more climate protection, the demand for environmentally friendly materials is currently increasing. This, in turn, may mean that more material manufacturers will produce larger quantities and achieve synergy effects, which will lead to lower prices in the foreseeable future. We are therefore in an ongoing process of sounding out how far we can currently go and when we can take the next, even more sustainable steps.

Even more sustainable with VAUDE’s "Made in Germany" apparel?

»We would like to meet the wishes of many consumers and produce even more products in Germany. Unfortunately, that is not an option for most of our apparel. Apart from the fact that the necessary sewing factories no longer exist in Germany, we would have to expect at least a doubling of the current sales prices. This would mean we would no longer be competitive in the outdoor industry.«

Why isn’t VAUDE clothing produced in Germany? We hear this question frequently. Of course, we also address it.

There are many reasons why. We could minimize CO2 emissions and capital-intensive pre-financing through shorter transport routes, and our proximity to producers would enable us to react more flexibly to demand and adjust production volumes. All this would also be advantageous from a business management point of view. Unfortunately, this is counterbalanced by wage costs. If we were to produce the Farley hiking pants from our example above in Germany, production costs would more than triple. The sales price would have to rise from €100 to over €200 in order to remain profitable as a company. However, this is currently impossible. The majority of the clothing industry shifted to Asia at the end of the 1980s. This means that there are no longer any production facilities for functional clothing in higher quantities in Germany. In addition, the production of the materials used in our apparel is also primarily located in Asia. The materials for production in Germany would therefore have to be transported here. There would only be CO2 savings through fewer transport routes if the supply industry were to relocate back to Germany as well. All this could perhaps be implemented in the long term. The question remains whether the recovery or reconstruction of the textile industry in Germany would really be more sustainable, because jobs would be lost in Asia and globalization can also be an opportunity for people worldwide to achieve a good standard of living.

For all these reasons, our current focus is less on where we produce our clothing and more on how. As a member of Fair Wear with Leader Status, we are committed to fair wages in Asia and would like to provide the people who produce our clothing there with working conditions that we can stand behind with our values. More about Fair Wear

Price is relative

In order to use a product for as long as possible, you can make an impact and improve your CO2 balance yourself by taking good care of it and, if necessary, making small repairs. That is why we already focus on good durability with robust materials and high-quality workmanship during the manufacturing of our products and make it possible to repair products yourself. We offer spare parts, repair instructions and an in-house repair service to achieve this. Read more about "Eternally yours".

An economic system for the benefit of all

We are therefore campaigning at the political level for legal regulations, such as a supply chain law that creates competitive conditions by ensuring that sustainable standards apply to all companies. In addition, we have proactively supported the realization of the German governmental "Grüner Knopf" seal and are fans and a pioneering company in the Economy for the Common Good with audited public interest balance sheets. The Economy for the Common Good is a vision for a long-term stable and fair economic system in which human rights and the environment are respected. The public interest balance sheet measures entrepreneurial success not only in terms of economic indicators but also in equal measure in terms of social and ecological aspects. Read more about "Economy for the common good".

In addition, we rely on long-term partnerships with our producers and suppliers, but of course also with you. Only by working together can we make sustainable and fair business possible.