We are proactive in our fight against hazardous substances

Clear strategy for chemicals management

It is our declared goal to ensure product safety and consumer safety for all of our product groups and to go beyond legal requirements.

The fashion industry is the second most polluting industry, just behind oil. 25 % of the world’s chemicals are used for fashion production. We are working to meet this challenge which is why there is a clear strategy for the management of chemicals at VAUDE.

- We place the highest emphasis on the safety for our customers.

- We refrain from using ecologically harmful and hazardous chemicals.

- Even without legal regulations, we are finding substitutes for dangerous substances.

- We take on comprehensive responsibility for people and the environment in our supply chain.

- We are transparent with all of the chemicals we use.

- We train and empower our partners in the supply chain.

Exceptionally strict limits with the Detox Commitment®

VAUDE Roadmap to Detox

Making your products and production processes as free of pollutants as possible is like climbing a mountain. The goal is clearly in sight, but you first have to build up your stamina, find your climbing team, divide the route into achievable stages and, if necessary, react to external influences such as the weather. That's how it’s been as we’ve followed the route toward Detox. The bluesign system partnership in 2001 was an important milestone, as well as projects and successes such as the PFC-free Apparel Collection 2018. All this started long before our Greenpeace Detox Commitment and will continue to challenge us again and again.

Here are the milestones we’ve passed on our way to Detox:

Clear limits for production and finished materials and products

Create your own infographicsThe introduction of an M/RSL is a big step. While compliance with limit values was previously observed in finished products only, it is now required throughout the entire manufacturing process including the production of yarns, weaving, dyes, coating/lamination and further finishing steps. This is quite a big step for us, and we also need the cooperation of our supply chain. However, we will continue to follow this path, as it will help us achieve great improvement for the people and the environment near our production sites. For all materials used, such as substances, ingredients and packaging material, VAUDE M/RSL is the basis of the business relationship.

The limits and prohibitions of individual substances listed in the VAUDE MRSL go far beyond legal requirements (REACH) and the requirements of other textile standards.

Our MRSL largely corresponds to the MRSL of the Textile Alliance, which is identical to the MRSL of ZDHC (Zero Discharge of Hazardous Chemicals). The ZDHC brings together several leading fashion and sports brands to jointly promote the phase-out of hazardous substances.

Consistent monitoring of the supply chain using the VAUDE M/RSL

VAUDE Green Shape Products: Suppliers must provide test reports.

Each supplier and producer must confirm compliance with the limits stipulated in the M/RSL - and, if necessary, back this up with test reports. For our partners, we have agreed on a VAUDE Hazardous Substances Program with a renowned testing institute.

How does a Harmful Materials Management System work?

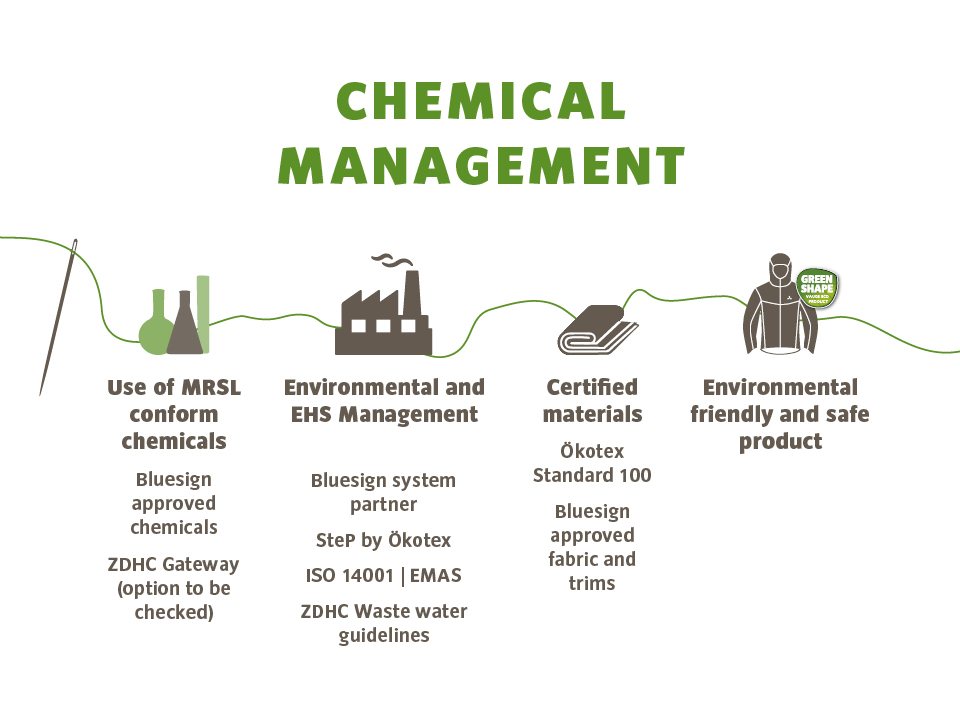

By consistently using MRSL-compliant chemicals and conforming with a certified Environmental Protection and Occupational Safety Management System in our production facilities, we work exclusively with certified materials that meet the highest sustainability standards. This also means that these materials were produced with little or no risk to the environment or the employees on site. We use these materials in your Green Shape product.

Your guarantee for an environmentally friendly and safe product.

When are tests carried out?

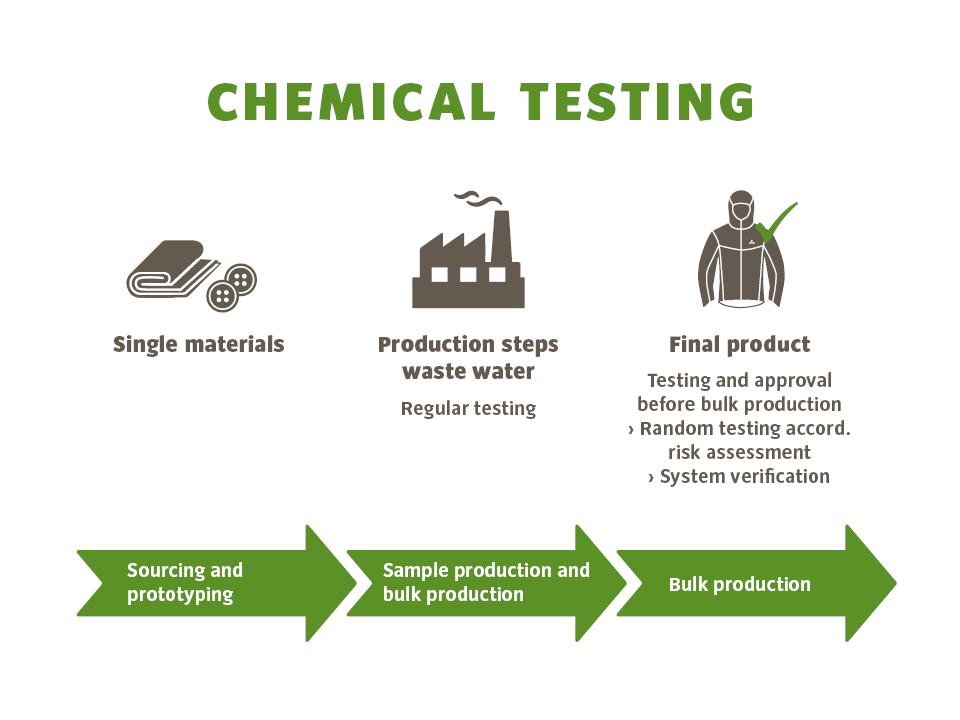

We require or carry out chemical tests on the individual materials and components even before the final selection of materials for the coming season. During the ongoing sample or main production, random wastewater tests are carried out by independent laboratories. Testing of the finished product is only carried out to monitor our upstream testing procedure.

Hazardous substance tests on materials and finished products

Wastewater tests

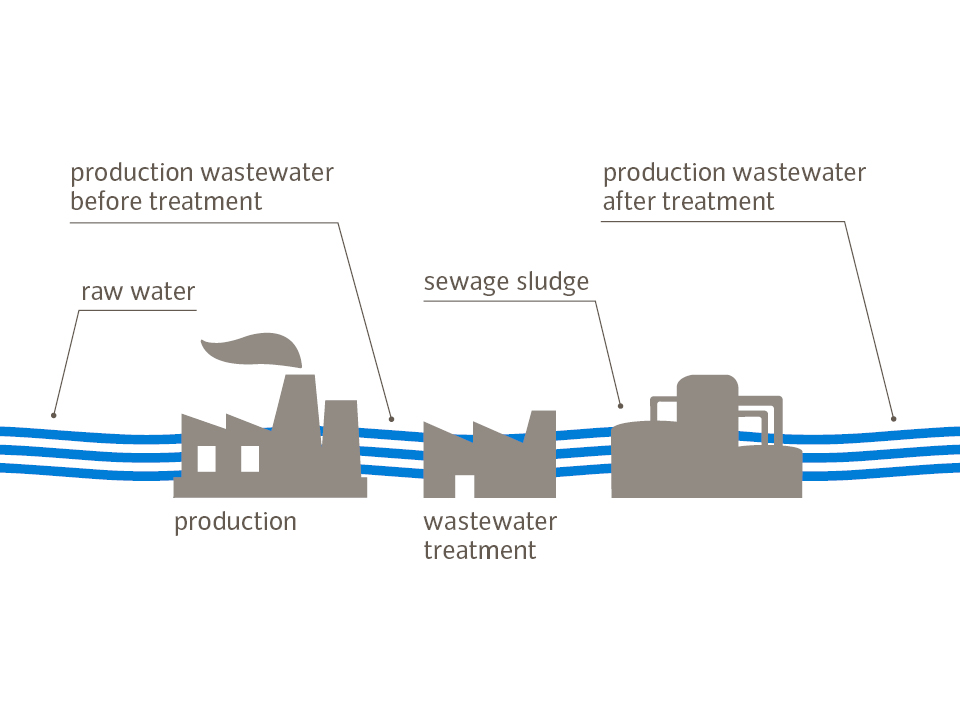

The Waste Water Guideline developed by ZDHC is currently gaining acceptance in the supply chain. This guide contains clear guidelines and procedures for sampling and chemical testing of wastewater and sludge in textile production. VAUDE bases its wastewater tests on these guidelines, as they specify all relevant points. This also enables closer cooperation with other brands. The test reports are uploaded directly from the testing institute to the ZDHC Wastewater Gateway platform and are available to all brands associated with this supplier.

This means that expenses and multiple inspections can be avoided and also that everyone can work together on improvement measures.

Results of Wastewater Tests

Overview of available wastewater tests

Create your own infographicsChallenges – chemicals of concern that we have not yet fully found substitutes for

APEOs are used as detergents in the production of textiles. Even if they are not detectable in the product, they cause enormous environmental damage. Due to inadequate legal regulations in some manufacturing countries, dispensing with APEOs remains a major challenge. We are currently working intensively with our supply chain on substitution and are already making good initial progress.

PFCs are used in the textile industry to manufacture water and dirt repellent products. They are not biodegradable, are released into the environment mainly via wastewater and are suspected of being carcinogenic. VAUDE has had PFC-free membrane production since 2011 and all clothing fabrics have been PFC-free since 2018. Currently we still use a PFC-finish for waterproof zips, tents, shoes and backpacks.

Phthalates are used as plasticizers, for example in PVC. They are suspected of being carcinogenic and some phthalates are considered to be teratogenic and harmful to fertility. Since 2018, not only our clothing, tents, mountain backpacks and shoes, but also our entire packs and bags have been PVC-free. We are working intensively on substitutes for other applications of phthalates.

Hologenated solvents contain halogens such as chlorine, bromine or iodine. They are often used in the textile industry to clean products. They can cause considerable damage to human and animal health. We are working at full speed on the substitution of this substance in our supply chain. For this purpose we are in close contact with our partners.

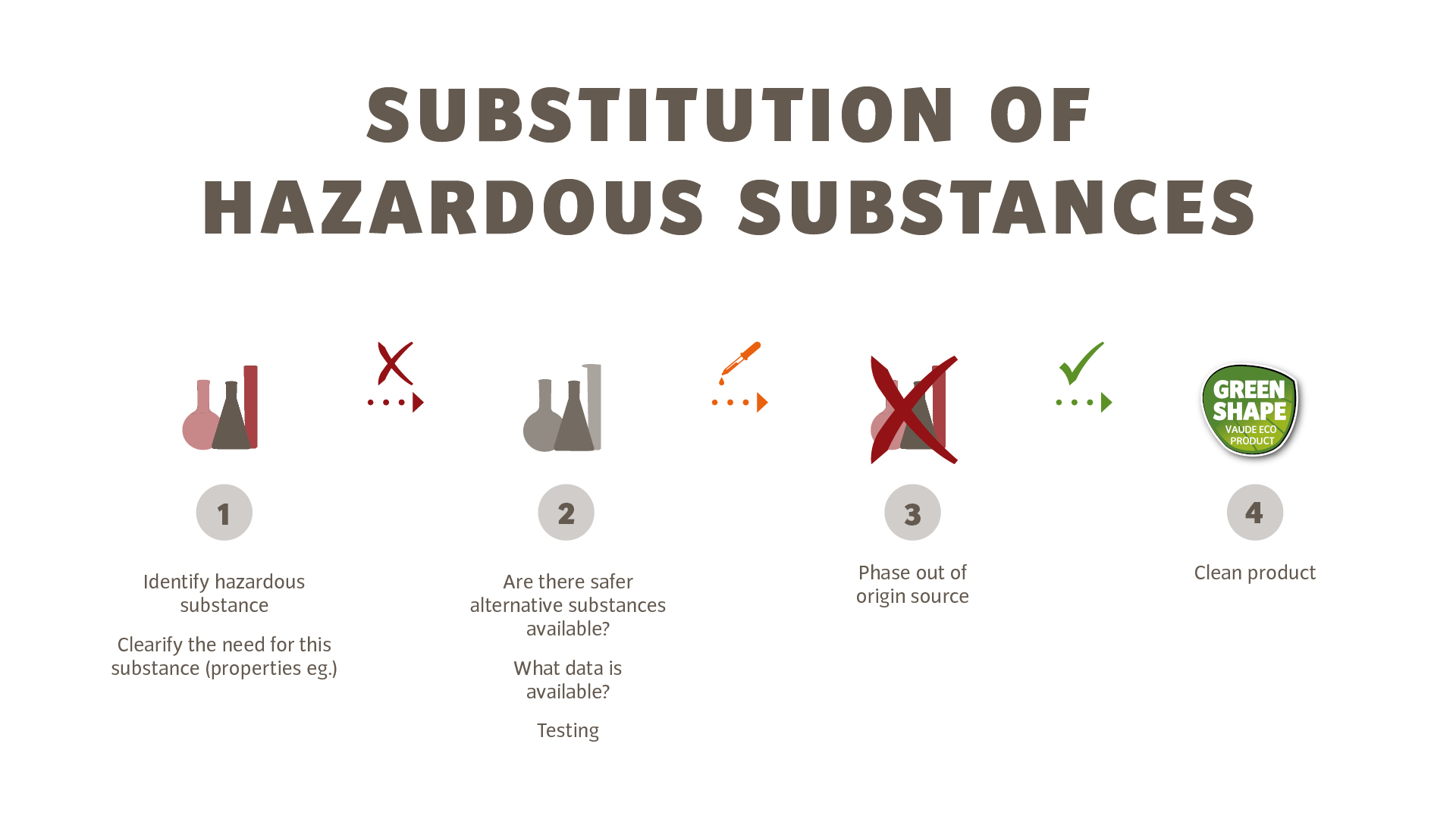

Substitution of hazardous substances

It is our declared goal to continue to work hard to find alternatives for chemicals of concern. To ensure compliance with our limits and regulations, we will continue to work on the transparency of our supply chain. We believe that we can achieve this through a partnership relationship with our suppliers and producers. In this context we want to encourage more suppliers and producers to publish results via platforms such as the ZDHC Gateway or the IPE platform.

| GRI: | 103 |

| GRI: | 102-11 |

| GRI: | 102-13 |

| GRI: | 102-48 |

| GRI: | 416-1 |

| GRI: | 416-2 |