Ambitious Goals

A look back at the events of 2019

Once again in 2019, VAUDE made significant progress with regard to sustainability and we have taken some important steps forward.

Corporate goals that are directly related to sustainability are published in our report. We do not publish our economic goals for competitive reasons.

Ambitious goals for the future

Our convictions haven't changed: We are continuing to work toward increasing our sustainability. In those areas where we are not completely satisfied, we are always setting new goals in order to achieve our corporate vision.

“As Europe’s most sustainable outdoor outfitter, we are contributing to making the world a better place to that tomorrow’s generation can enjoy the outdoors with a clear conscience. We are taking a stance and setting sustainability standards worldwide.”

We have set ourselves high standards and are steadily setting ourselves new, ambitious goals – which also bring along their own challenges. We are facing up to these challenges and tackling them head on. More at – Our Challenges

Our stakeholders also give us extensive feedback. We are proactive in analyzing our strategies with regard to their concerns and examine how we can improve both our CSR services and our communication. Read more at – "Involving Stakeholders".

Systematic management approach and goal measurement

We continually and consistently measure our sustainability performance. Our goals are defined with specific target figures and timeframes. Regular analysis of how well we are reaching our goals ensures that the process continues to develop and improve.

More about this here

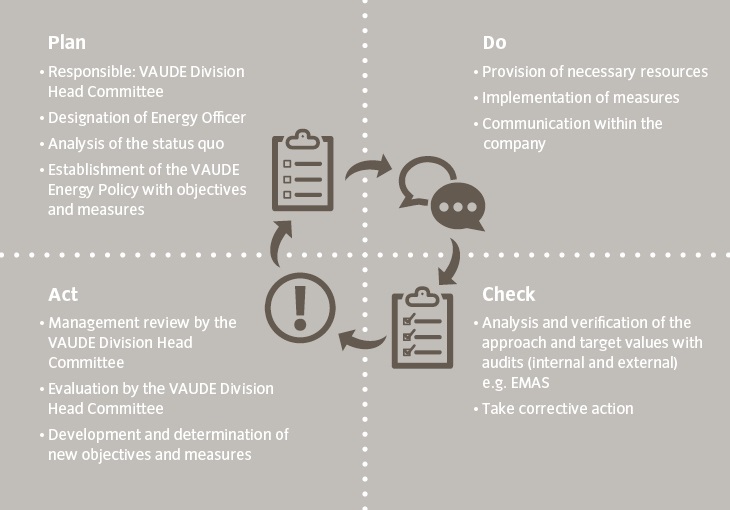

As we are analyzing our goals, we use the Plan-Do-Check-Act (PDCA) method. This means that we carefully identify specific measures for achieving our goals. (»SMART«) After one or more measures for achieving the goal have been implemented ("do"), the procedure and the target values ("check") are always reviewed. Action includes reviewing the results, which are then included in future objectives, target figures and measures (“act”). This ensures the achievement of a systematic, continuous, improvement process.

Implementation of the VAUDE energy management with the plan-do-check-act principle

Overview over our company goals

| GRI: | 102-14 |

| GRI: | 103 |

We are economically self-sufficient and positioned for a promising future.

| Strategic Measure | Key performance indicator | Actual Value 2017 | Target Value 2018 | Actual Value 2018 | Target Value 2 019 | Actual Value 2019 | Target Value 2020 |

|---|---|---|---|---|---|---|---|

|

Increasing/stabilizing of the equity ratio See also: "Sustainable Business is Worthwhile" |

Equity ratio |

52,10 % |

52,90% |

53,40 % |

58,20 % |

64,70 % |

51,00 % |

|

Increase sales |

Sales |

6,30 % |

6,20 % |

5,30 % |

1,10 % |

- 0,5 % |

4,90 % |

GRI Aspect: Economic Performance

We are transparent and authentic.

| Strategic Measure | Key performance indicator | Actual Value 2017 | Target Value 2018 | Actual Value 2018 | Target Value 2019 | Actual Value 2019 | Target Value 2020 |

|---|---|---|---|---|---|---|---|

|

Transparency in the supply chain: we publish the locations of our producers and material manufacturers |

Publication |

List of producers and suppliers in the Sustainability report - please click here to download. |

List of producers and suppliers in the Sustainability report - please click here to download. |

List of producers and suppliers in the Sustainability report - please click here to download. |

Publish full supply chain for at least five VAUDE products of our summer 2020 collction online. We are currently testing different technical solutions. |

Planning for 30 Highlight Products Apparel so far 1 (sewing company, certifications etc.) |

Presentation of 30 Highlight Products on Trustrace platform, planning expansion of the presentation for the entire Apparel Collection starting Summer 2021 |

|

Voice of Consumer: End consumer satisfaction measured and involvement of end consumers by means of active dialog |

Satisfaction Score |

Satisfaction Score: 76 % |

Increase Satisfaction Score. |

79,10 % |

Stabilize Satisfaction Score. |

78,00 %

|

Maintaining the high Satisfaction Score. |

|

Active dialog with environmental stakeholders on environmental management issues in the supply chain |

|

Dialog with experts on the further development of our Green Shape Concept postponed to 2018. |

Dialog workshop with experts to further develop our Green Shape concep |

Stakeholders have been involved in the evaluation and development of the VAUDE Green Shape Concept, e.g. for VAUDE repairability index, VAUDE Vendor Management, and for VAUDE Green Shape Campus. |

Continue and formalize stakeholder involvement in further development of Green Shape Concept. |

Targeted involvement of stakeholders in the continued development of the Green Shape Concept: |

Development of requirements for the continued recognition of Green Shape as a standard, with a view to independent verifiability and for the Grüner Knopf |

GRI Aspects: Advertising, Identification of Products and Services, Compliance (Product Identification), Policy

Our products are sustainable and innovative.

| Strategic Measure | Key performance indicator | Actual Value 2017 | Target Value 2018 | Actual Value 2018 | Target Value 2019 | Actual Value 2019 | Target Value 2020 | Comment |

|---|---|---|---|---|---|---|---|---|

|

Increase overall proportion of environmentally friendly products |

Total proportion of environmentally friendly products - Total Collection (Green Shape) |

Winter 2018: 83 % Summer 2019: 78 % |

Increase the proportion of products |

Winter 2019: 86 %

|

Increase the proportion of products |

Winter 2020: 89 % |

Increase the proportion of products |

|

|

|

Total proportion of environmentally friendly products in the Apparel Collection (Green Shape) |

Winter 2018: 95 % Summer 2019: 98 % |

Increase the proportion of products |

Winter 2019: 98 %

Summer 2020: 97 % |

Increase the proportion of products |

Winter 2020: 96 % |

Increase the proportion of products |

|

|

|

Overall proportion of environmentally friendly products in the Hardware Collection (Green Shape) |

Winter 2018: 95 % Summer 2019: 98 %

|

|

Winter 2019: 73 %

Summer 2020: 72 % |

|

Winter 2020: 81 % |

Increase the proportion of products |

|

|

|

Total proportion of bluesign® certified fabrics in the Apparel Collection |

Winter 2018: 68 % Summer 2019: 61 %

|

|

Winter 2019: 73 %

Summer 2020: 72 % |

no longer monitored separately due to integration in Green Shape |

Winter 2020: 70 % |

Increase the proportion of products |

The proportion of bluesign certified fabrics in the clothing collection is decreasing as we have also opened ourselves up to other strict 3rd party certifications within our Green Shape 2.0 concept. |

|

|

bluesign® product percentage overall Collection |

Winter 2018: 68 % Summer 2019: 61 %

|

|

Winter 2019: 55 % Summer 2020: 60 %

|

no longer monitored separately due to integration in Green Shape |

|

|

The proportion of bluesign certified fabrics in the clothing collection is decreasing as we have also opened ourselves up to other strict 3rd party certifications within our Green Shape 2.0 concept. |

|

|

bluesign® product proportion in the Apparel Collection |

Winter 2018: 68 % Summer 2019: 61 %

|

|

Winter 2019: 55 % Summer 2020: 60 %

|

no longer monitored separately due to integration in Green Shape |

|

|

The proportion of bluesign certified fabrics in the clothing collection is decreasing as we have also opened ourselves up to other strict 3rd party certifications within our Green Shape 2.0 concept. |

|

|

bluesign® product percentage of the Hardware collection |

Winter 2018: 68 % Summer 2019: 61 %

|

|

Winter 2019: 55 % Summer 2020: 60 %

|

no longer monitored separately due to integration in Green Shape |

|

|

The proportion of bluesign certified fabrics in the clothing collection is decreasing as we have also opened ourselves up to other strict 3rd party certifications within our Green Shape 2.0 concept. |

|

Increase the proportion of recycled materials used |

Proportion of the total collection of recycled materials |

Winter 2018: 18 % Summer 2019: 18 % |

Increase the proportion of products |

Winter 2019: 27 %

Summer 2020: 28 % |

Increase the proportion of products |

Winter 2020: 30 % |

Increase the proportion of products |

|

|

|

Proportion in the Packs 'n Bags collection of recycled materials |

|

Winter 2019: 54 % Summer 2020: 56 %

|

Increase the proportion of products |

Winter 2020: 41 % |

Increase the proportion of products |

|

|

|

Manufacture products with PFC-free finish |

Proportion of PFC-free products in the collection |

Apparel Collection: |

Increase the proportion of products in the other main product groups. Complete phase-out by 2020. |

Apparel:

Winter 2018: 100 % |

Increase the proportion of products and increase in other product groups. Complete phase out until 2020. |

Apparel Collection: |

Increase missing shares to 100% |

We are dependent on the availability of a marketable C0 chemistry to further increase the share of waterproof products with C0 finish |

|

Products Packs 'n Bags PVC-free |

Proportion of PVC-free products in the Packs ´n Bag collection |

Winter 2018: 95 % Summer 2019: 100 % |

By 2020: 100 % |

Winter 2019: 100 % |

100 % PVC free products |

Winter 2020: 100 % |

Maintain proportion |

|

|

Extension of product life - See also: "Neverending responsibility" |

Reuse rate (proportion of product complaints that are recycled) |

96 % |

Increase re-use rate |

94 % |

Increase repair rate |

88 % |

Increase recycling rate |

|

|

Extension of product life - See also: "Neverending responsibility" |

Publish online repair and maintenance instructions |

Publication of 30 online repair and maintenance manuals |

Veröffentlichung von 30 online Reparatur- und Pflegenanleitungen Increase re-use rate |

30 online care & repair guides published on vaude website and iFixit website |

Increase number of online care & repair guides

|

30 online repair instructions, currently no further instructions planned or required |

|

|

|

Introduce environmentally friendly transport packaging - See also: "Packaging" |

|

Packaging of the Green Shape Core Collection in 100 % recycled polybags |

Complete conversion to 100 % recycled polybags |

Packaging of the Green Shape Core Collection in 100 % recycled polybags. |

Complete conversion to 100 % post consumer recycled polybags |

Actual value 2019 cannot be determined because the procurement of the bags and thus the recycling rate was the responsibility of the producer. In the course of 2020, the manufacture and logistics will probably be changed over, so a reliable analysis will only be possible in the next report. |

Conversion of the manufacture and logistics at the Obereisenbach site to recycled polybags. |

|

GRI Aspect: Materials, Products and Services, Customer Health and Safety

Our company is climate neutral

| Strategic Measure | Key performance indicator | Actual Value 2017 | Target Value 2018 | Actual Value 2018 | Target Value 2019 | Actual Value 2019 | Target Value 2020 |

|---|---|---|---|---|---|---|---|

|

Climate neutrality is achieved, not only with regard to the OEB headquarters, but also for the entire company, all products and logistics. |

Science Based Targets (SBT) are set and achieved. |

|

|

|

|

Commitment to science based targets has been made (Oct 2019)

|

Objective SBT Deadline by Oct. 2021 (in accordance with SBT regulations). Implementation SBT in accordance with the timeline defined in SBT (at least in accordance with the Paris Climate Convention: at least 50% less emissions by 2030, climate-neutral by 2050) |

|

Development of an energy, water and waste management system - see also: "Energy management" |

Increase energy efficiency by 20 % by 2020 (base year 2008) |

Our new energy management tool will be introduced in 2018 to provide the data basis for calculating energy efficiency. |

Increase energy efficiency |

Energy management software introduced. Evaluation and monitoring of individual buildings / systems is still being set up. |

Increase energy efficiency |

Software has been introduced and after some initial problems is now working. Consumption of the individual buildings is being measured and evaluated individually. |

Optimization of energy management according to buildings and consumers |

|

|

Reduce residual waste manufacture per metric ton of production output of finished products (base year 2016) |

0,07 |

Reduce Manufaktur residual waste per ton of production output finished products |

2,48 (high volatility of figure depending on waste sorting, materials used and styles produced) |

Reduce Manufaktur residual waste per ton of production output finished products |

1,73 t |

Reduce Manufaktur residual waste per ton of production output finished products |

|

Implementing the mobility concept - see also: "Carbon Footprint" |

Reduce emissions from passenger transport (business travel and commuting) by 10% by 2020 (base year 2015) |

Goal was not reached by 17% (data corrected after discovery of mistake) |

Reduce emissions from passenger transport |

20 % fewer emissions from passager transport compared to 2015 (base year) and 31 % fewer compared to 2017. |

Reduce emissions from passenger transport |

25 % less emissions from passenger transport compared to 2015 (base year) and 4% less compared to 2018 (previous year) |

Reduce emissions from employee mobility (business travel and commuting) another 25% by 2024 compared to 2018 |

|

Implementing the mobility concept - see also: "Carbon Footprint" |

Bike Commuting kilometers |

42.603 |

55.000 |

44.970 |

Further promote environmentally friendly commuting to reduce car traffic. |

46.018 |

Continuation of the VAUDE mobility concept with the aim of avoiding car kilometers. |

|

Green Logistics (analyzing the flow of merchandise and optimizing emissions resulting from this) - see also: "Merchandise Logistics" |

Concept is available |

Implementation of operational measures: e.g. rail transport is checked before every transport decision from Asia, partial routes are delivered by rail. |

Implementation of further measures, e.g. route handling in the course of the introduction of a new business management software 2020. |

Further implementation of operational measures e.b. train transport instead of air transport, increased load capacity efficiency, consolidate deliveries. |

Further implementation of Green Logistics measurements like software supported route handling in contect with implemenation of new enterprise management software. |

Continued implementation of operational Green Logistics measures: e.g. rail transport instead of air freight, improvement of container utilization, consolidation of deliveries etc. |

Implementation of additional measures e.g. route handling in the course of the introduction of a new business management software 2020. |

We achieve high environmental standards in the supply chain.

| Strategic Measure | Key performance indicator | Actual Value 2017 | Target Value 2018 | Actual Value 2018 | Target Value 2019 | Actual Value 2019 | Target Value 2020 | Comment |

|---|---|---|---|---|---|---|---|---|

|

Ensure materials traceability |

Selection of a new GOTS-certified producer, after insolvency of the previous producer |

Our cotton products have been awarded the GOTS seal of approval |

GOTS certified cotton suppliers in Lithuania and Portugal |

Labelling our cotton products with GOTS compliant fiber blends with the GOTS seal |

3 products with GOTS label |

Continue to develop products with GOTS-compliant fiber blend and label them with the GOTS seal |

|

|

|

|

RWS Certification VAUDE |

RWS Certification of our material suppliers |

Cooperation with GOTS certified producers in Portugal and Lithuania |

GOTS/RWS certification of our material suppliers |

Implementation of standards in the supply chain under construction |

GOTS/RWS certification of our material suppliers |

|

|

|

Securing environmental standards in the supply chain |

100 % |

100 % of manufacturers signed VAUDE MRSL |

Selection of GOTS/RWS certified producers and suppliers |

100 % of manufacturers signed VAUDE MRSL |

100 % |

Target was reached in 2019. |

Since 2016, we have used a stricter MRSL (which refers to the manufacturing process) instead of an RSL (which refers to the finished product). |

|

|

|

98 % |

100 % of nominated suppliers signed VAUDE MRSL |

98% |

100 % of nominated suppliers signed VAUDE MRSL |

100 % |

Target was reached in 2019. |

Since 2016, instead of an RSL (which refers to the finished product), we have been using a more stringent MRSL (which refers to the manufacturing process). |

|

|

Environmental management in the supply chain - see also: "Suppliers" |

|

Project completed in 2017. Follow-up project application prepared and submitted in 2018 together with other brands. |

Implementation of follow-up project |

follow up project was not feasible. VAUDE implements own measures. |

Roll out of Environmental Stewardship Club in more countries and to more suppliers |

Renamed Vendor Clubs 1st Vendor Club in Vietnam for sewing operations (incl. sewing operations in China, Cambodia and Myanmar) and 3rd Vendor Club in Taiwan for wet processes |

Vendor Clubs in Taiwan and VIetnam maintained. Additional Vendor Club with top management regarding Science Based Targets |

The name was changed to Vendor Club, as all three pillars of our supplier management (environment, social, quality) are to be part of the Vendor Clubs in future |

|

Brand Performance Check FWF Results: Production sites audit and CAP monitoring - see also: "Leader Status at the Fear Wear Foundation" |

Overall Results Brand Performance Check |

Leader |

Maintain Leader Status |

Leader |

Maintain Leader Status |

Leader

|

Maintain Leader Status |

|

|

|

Benchmarking Score in % from the FWF Brand Performance Check |

94 % |

maintain |

88 % |

Maintain our performance level of "very good" |

88 % |

Maintain our performance level of "very good" |

The actual value for 2017 is not comparable with the actual value for 2018, as the FW has tightened its criteria. |

|

|

Percentage of audited production sites |

100 % |

maintain |

100 % |

maintain |

100 % |

maintain |

|

GRI Aspects: Evaluation of Suppliers in Terms of Ecological Aspects, Grievance Procedures in Relation to Environmental Aspects, Grievance Procedures Regarding Working Practices

Our employees are satisfied and we are an attractive employer.

| Strategic measure | Key performance indicator | Target Value 2018 | Actual Value 2018 | Target Value 2019 | Actual Value 2019 | Target Value 2020 | Comment |

|---|---|---|---|---|---|---|---|

|

Improved results in a survey of employee satisfaction |

Participation in the BGM Beschäftigungsbarometer (employee survey) of the Techniker Krankenkasse and the Institute for Occupational Health |

Survey conducted |

Evaluation of the results and implementation of the need for action |

The survey revealed an employer loyalty clearly above the reference values used (population / comparable companies). |

Second participation in the BGM employment barometer (employee survey) of the Techniker Krankenkasse and the Institut für Betriebliche Gesundheit (1st follow-up); or in view of changed conditions due to the corona pandemic 2020 implementation of an alternative with a stronger situational reference to determine the state of health of employees and the possibility of direct intervention at employee level |

The results of the first survey (at the end of 2018) confirm that our employee satisfaction is above average. Even if there was no new survey in 2019 that would have confirmed this once again, we can assume, based on the response of our employees, that our satisfaction and loyalty to VAUDE will remain high. |

|

|

|

5,00 % |

5,97 % |

5,00 % |

9,14% |

5,00 % without consideration of marginally employed persons |

As we consider the fluctuation rate, excluding temporary staff etc., to be more informative for the interpretation of employee satisfaction, we refer our annual target to this value. |

|

|

Supporting employee health |

5,00 % |

7,05 % |

5,00 % |

Not specified (see commentary) |

The aim is to maintain or fall short of the previous year's level |

As we are currently revising the calculation method, we are not disclosing this value for the 2019 reporting year. The key figure used temporarily is the average number of sick days per employee: 12.7. |

|

|

Promoting diversity and equal opportunities |

Increase the proportion of women in management positions (per category) |

Mid to long term goal: |

Overall: 43 % |

Mid to long term goal: |

Total: 44 % |

|

We are taking steps toward our goal of increasing the percentage of women in management positions. We are pleased with our low employee turnover rate and want to maintain this. This is the reason that the rate of women in management can only be substantially changed over the long term. |

GRI Aspects: Employment, Employee-Employer Relationship, Training and Professional Development, Diversity and Equal Opportunities, Equal Pay for Women and Men, Equal Treatment, Compliance (Social), Indirect Economic Performance