Is responsible production in Myanmar possible?

Production in Myanmar - a loyal partnership

VAUDE has a longstanding partner with whom we have made a number of your VAUDE products in Myanmar. This is in a production facility owned by a Taiwanese partner that we have been working closely with for many years.

In addition, since 2019 we have been working with another Taiwanese partner which manufactures our products in two of its production facilities in Myanmar.

We are aware of the risks that production in Myanmar brings with it and put considerable effort into ensuring that the production facility meets our high standards. One example is a training project that we implemented in Myanmar that won honors from FW.

We have full transparency throughout the production facilities and are familiar with the working conditions there. Our partners are also strongly committed to improving working conditions and see it as part of their responsibility towards their employees. One producer was awarded the Social Compliance Excellence Award in 2016 for their commitment by the Textile Industry Association in Myanmar (MGMA). We are very pleased that our production partners are on the right track.

Why does VAUDE produce in Myanmar?

Our partner had already started production in Myanmar in 1999 ¬– at the time mainly for the American market. After the USA embargo in 2003, many of our partner’s customers canceled their orders. So the producer asked us whether we could move some production to Myanmar. Due to the embargo, our partner’s Myanmar production site was facing closure and badly needed new customers. In order to maintain jobs there, VAUDE decided to expand its production to Myanmar in 2003. Since then, we have manufactured a small selection of products in this factory.

Today the factory employs almost 2,000 people. VAUDE orders make up 30 % of the total capacity. The production facility in Myanmar accounts for 9 % of the total turnover for all VAUDE product groups.

FW allows the production in Myanmar only under certain conditions

We think that it's good that FW sets stricter requirements for production in Myanmar. Despite the fact that Myanmar has made some progress with civil and political rights, it still counts as a high-risk country because there is a good chance that labor standards won't be met. In addition, the annual FW Brand Performance Check (BPC) monitors us to ensure that we are meeting all requirements and fulfilling our responsibilities.

You can read FW's detailed regulations on production in Myanmar here

Monitoring of the production facilities in Myanmar

Like all our other production facilities, the production sites in Myanmar are audited by Fair Wear every 3 years. If deviations are discovered during the audit, these are recorded in a corrective action plan (CAP).

Our CSR employees don’t just check on the progress made, but work together with the producers, offering them expert advice for implementing the measures. These CSR employees visit the production facility several times per year.

In addition, wages will be reviewed and a comparison of wages paid with the minimum wage will be created. We've decided to represent wages in PPP$ rather than local currency. Why?

Because salaries of different countries of production can’t be compared if they are given in local currency when you don't really know how much things cost there. For this reason, we have converted wages and also minimum wages into their purchasing power using the World Bank's conversion factor.

2018 wages in Myanmar

Create your own infographicsSocial Compliance Excellence Award

We are very proud that our producer was awarded the Social Compliance Excellence from the Textile Industry Association in Myanmar (MGMA) in 2016.

Skills training

SMART Compliance Academy

For this reason we have cooperated with SMART Myanmar for several years. SMART is a European Union project with the goal of promoting sustainable textile production in the country. Our producer has participated in the SMART Compliance Academy. Within the framework of this 6-month training, the fundamentals of a sustainable management system are taught in workshops and factory visits, and the system is then put into practice. In addition, our producer took part in additional training in the areas of personnel management and intercultural communication.

Communication and Dialogue Workshop

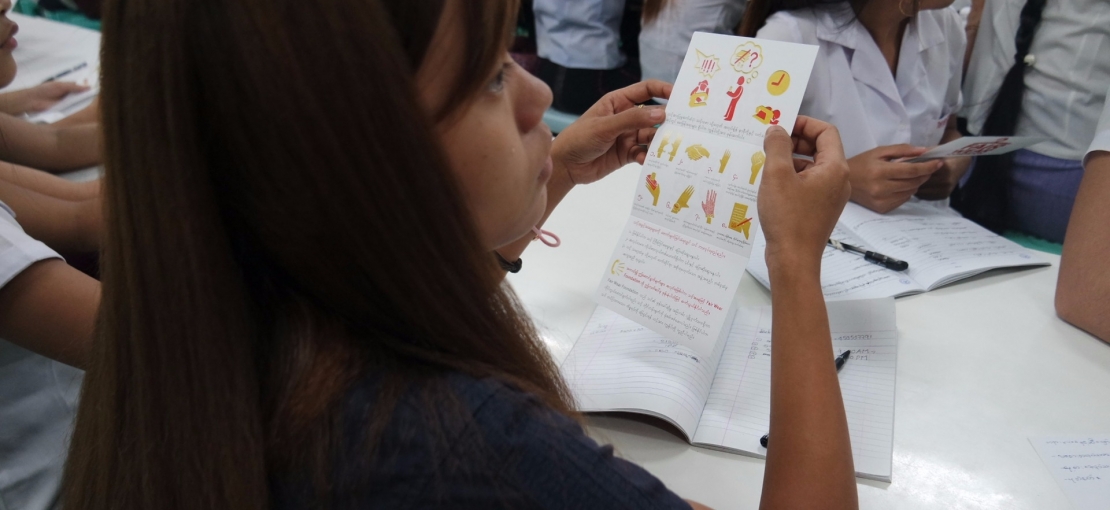

A training course on good communication at the workplace and dialogue with management was conducted in 2019 at a producer in Myanmar. The content of the training was as follows:

- Effective communication in the workplace

- Effective internal dialogue

- Development of an internal complaint system

In the course of the audit and as a result of numerous complaints, we found that employees have no confidence in structures of internal dialogue. For this reason, we worked together with SMART Myanmar to set up a training course for our producer that lasted several months. A continuation is planned for this year.

VAUDE honored by FW

Together with the brands Jack Wolfskin and Salewa, we conducted a training project in Myanmar. For this, we were awarded with the Best Practice Award by FW. Read more here