Social responsibility in the supply chain

Leader Status at Fair Wear

VAUDE is audited annually by FW. During these audits, we must demonstrate that we are fulfilling our obligations to create fair working conditions for our producers. FW has once again awarded us the best possible category, confirming our extraordinary commitment and exemplary system.

For more details, check out the FW report.

Fair Wear

About Fair Wear

FW is a multi-stakeholder organization which believes that enacting change in the supply chain is a joint responsibility. This fits well with our approach at VAUDE, because we also believe that the responsibility for fair working conditions does not lie with the producer alone; we as a client can also make a major contribution. For this reason, FW regularly checks whether we are meeting the requirements placed on us.

FW Scope – cut make trim

Our direct business partners for the manufacturing of our products are our producers. As garment makers, they manufacture our products: They prepare the fabrics, cut out pattern pieces and sew them into finished products. Quality control and packing finish off the process.

In general, the textile and clothing industry is very labour intensive. Because making clothing primarily involves manual processes that require a large number of workers, FW focuses on this part of the process. This gives us the opportunity to improve working conditions for the largest number of workers in our supply chain.

Cooperation with FW members

Fair Wear provides us with the opportunity to cooperate with other member companies. If, for example, other manufacturers work with the same producer, we can perform a joint audit. This is advantageous in that the producer must be audited only once, reducing the waste of resources – both the producer’s and ours. Another positive aspect is that in working together, we have a greater degree of influence on the producer. For example, after a joint audit or during joint training programs, we can work together with other member companies to enhance the effects of the improvement process. Read more here

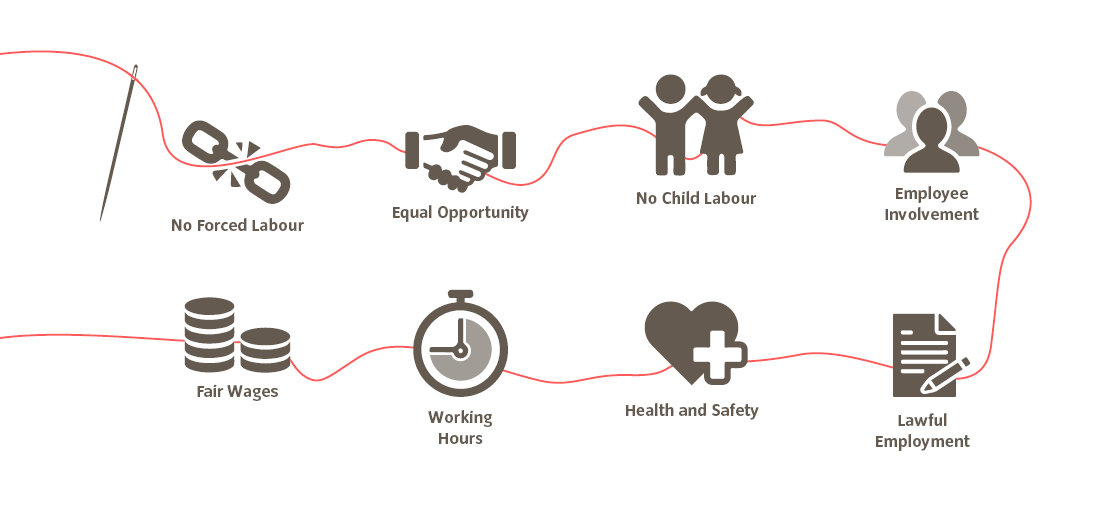

FW Code of Labour Practices (CoLP)

Code of Labour Practices is part of each contract

All partners must sign a commitment to comply with the Code of Labour Practices and participate in the improvement process.

Billboard for workers

Each production site must post FW's information sheet listing the 8 labour standards from the Code of Labour Practices and providing information on FW's complaint hotline. In addition, the workers must be informed about the content of the CoLP.

Both our local employees and FW auditors regularly check whether this information sheet is posted.

Training for the workers and management

In addition, all production sites receive regular training on the content of the Code of Labour Practices and the complaint hotline.

100 % of our production facilities are monitored

Audits of FW-relevant producers

To ensure objective examination of working conditions at the production facility, producers are audited by independent FW auditors. During the audit, FW closely examines whether or not the producer is complying with the contents of the Code of Labour Practices and applicable laws. Any discrepancies are recorded in a corrective action plan (CAP).

An FW audit includes the following:

- Inspection of the entire production site to evaluate occupational safety

- Review of relevant documents

- Interviews with workers and management

All interviews are conducted anonymously. Interviews take place both within and away from the production site.

In addition, FW surveys local stakeholders on each of the eight standards regarding the conditions and implementation of these standards in the country.

What happens after the audit?

An audit alone does not change anything. The actual work begins after the audit. After each audit, FW and production facility agree to a binding corrective action plan (CAP) in which all deviations are listed.

We discuss this corrective action plan intensively with our producers. Together we develop joint solutions and also a schedule that specifies the date by which the respective deviations should be remedied. The challenge is to anchor the implemented measures in a sustainable manner.

Regular Re-Audits

In general, re-audits are carried out every three years. This corresponds to the guidelines of FW. If a producer does particularly poorly, we initiate a verification audit earlier to check what improvements have been achieved and what issues still need to be addressed.

Are subcontractors also checked?

Yes! Because the people who work there are also involved in the manufacturing of our products, we want to ensure fair working conditions at these locations as well. All of our producers are committed to disclosing their subcontractors.

We have the same process with subcontractors that we have with our direct producers. Before work begins, the subcontractor must pass a confirmation process for our production. If the facility is approved, it is included in the same monitoring process that is used for our direct partners.

What about embroidery and printing?

Here, too, we demand maximum transparency from our partners. If various production steps (such as embroidery, printing or washing) cannot be carried out internally, the producer must inform us. We are currently training selected partners to give them the competence to monitor the outsourced production steps themselves.

Deviations in the audit

| Production Facility | C1 | C2 | C3 | Total C | V1 | V2 | V3 | V4 | V5 | Total V | CM | BLR |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

VAUDE Purchasing Practices |

1 |

1 |

1 |

3 |

1 |

1 |

1 |

1 |

1 |

5 |

0 |

0 |

|

VAUDE-Monitoring System |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

|

Management System-Producer |

0 |

0 |

1 |

1 |

1 |

1 |

4 |

5 |

2 |

13 |

0 |

2 |

|

Communication |

2 |

3 |

2 |

7 |

0 |

3 |

0 |

0 |

0 |

3 |

2 |

0 |

|

Forced Labour |

0 |

0 |

0 |

0 |

0 |

0 |

3 |

2 |

0 |

5 |

0 |

0 |

|

Discrimination |

0 |

0 |

0 |

0 |

2 |

0 |

1 |

0 |

0 |

3 |

1 |

0 |

|

Child Labour |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

|

Freedom of Association / Collective Bargaining |

1 |

1 |

1 |

3 |

3 |

3 |

2 |

2 |

1 |

11 |

1 |

1 |

|

Payment of a living wage |

3 |

5 |

2 |

10 |

3 |

4 |

2 |

0 |

1 |

10 |

3 |

3 |

|

Working Hours |

4 |

3 |

2 |

9 |

4 |

3 |

1 |

2 |

1 |

11 |

0 |

2 |

|

Health and Safety |

4 |

4 |

9 |

17 |

17 |

14 |

13 |

16 |

11 |

71 |

13 |

8 |

|

Legally binding employment relationsship |

0 |

1 |

1 |

2 |

2 |

3 |

0 |

0 |

0 |

5 |

0 |

0 |

|

Total |

15 |

18 |

19 |

52 |

33 |

32 |

27 |

28 |

17 |

137 |

20 |

16 |

Social standards in the deeper supply chain

In recent years we have worked diligently on the transparency of our producers (the first stage of our supply chain), including verification and further development. Now we are going one step further and are expanding our commitment to the entire supply chain. Read more here

Supporting the improvement process

Our CSR employees who live and work in China and Vietnam and speak the local languages, support our producers and suppliers in the implementation of social standards. They assist our partners with their knowledge and experience. They also make regular follow-up visits to monitor the status of the corrective action plan.

| GRI: | 103 |

| GRI: | 408-1 |

| GRI: | 414-2 |