Fishing nets, coffee grounds, PET bottles

As you can see from the following graphic, recycled products are already being used in many areas of our lives.

Use of Recycled Plastics in Germany 2017

Create your own infographicsThe fact that textiles are not listed separately in this graph shows how high the potential in this area remains. There is still room for improvement. We are working with our partners on solutions for a circular economy and in our product development on recyclable products as well as on continuously increasing the use of recycled materials.

Our objective:

By 2024, 90 % of all VAUDE products will have a recycled or biobased material content that is greater than 50 %.

The types of recycled materials we are already using follows.

Plastic packaging recycling

Innovative, climate-friendly and extremely stable – this describes a new, sustainable material made from recycled household packaging that we’re using for the first time for the back panels of our VAUDE bike bags.

In Germany, plastic packaging for items such as spaghetti, bottles or empty yogurt containers are recycled in the “yellow bag program.” This waste is sent to large sorting plants where it is separated by type of plastic.

Yogurt containers, detergent containers, disposable flower pots and cosmetics packaging are made of polypropylene (PP), a material we can use for the back panels of our panniers.

After they are coarsely sorted, the plastics are mechanically shredded, washed and separated based on material density. The plastic flakes are then dried, melted and processed into a new granulate suitable for manufacturing new products, such as our back panels.

This is how the secondary raw material is produced from plastic packaging of German households that is collected and sorted in an innovative recycling process.

About 3 kg of packaging waste is processed for one back panel, reducing CO2 emissions for material production by 54 % *. The raw material obtained from this packaging waste is called 'Procylen®3' and was provided with components especially for VAUDE to make it an extremely stable plastic for the new VAUDE back panels.

This recycling method protects the climate and helps to make good use of Germany's plastic waste while conserving fossil resources.

*

Source link:

"LCA Recycled-Ressource, Fraunhofer Institute UMSICHT on behalf of INTERSEROH Dienstleistungs GmbH, 2018."

Materials made from marine pollution

ECONYL® nylon is made from fishing nets and other nylon waste. Abandoned fishing nets that are floating freely in our seas are turned into high quality clothing. Now that’s some positive news for the planet!

The WWF considers the issue of plastic in our oceans to be one of the most pressing environmental problems of our times. Plastic garbage pollutes our waters, releases toxins into the environment and threatens marine plants and animals. Ghost nets are doing a great deal of harm in the world’s oceans and dolphins and whales can get entangled in them.

From fish catcher to eye catcher

Aquafil, our suppliers for ECONYL® polyamide yarn, is collecting nets and other nylon waste from landfills and oceans and recycle them into new, high quality materials.

The preparation of the fishing nets – including cleaning, chemical depolymerization and repolymerization processes – takes place in Europe. Thanks to the ECONYL® Regeneration System, New polyamide yarn is created from pollution – with the same chemical qualities and the same functionality as polyamide made from petroleum.

So for your new product, not only is waste eliminated, but oil, energy and emissions are conserved as well. Fact and figures, photos and videos are available at www.econyl.com

Polyamid Recycling

Due to the scarcity of recycling waste, some suppliers recycle the waste that is generated during production. This is known as post industrial or pre consumer recycling.

In the textile industry, waste is generated in various processes. Examples include the winding of yarn bobbins in spinning mills, adjusting the machines or fabric quality in weaving mills, or rest materials from pattern pieces at clothing manufacturers. These types of residual waste are collected and recycled.

These measures also help to cut down on waste and conserve resources and are an important step in the right direction as they help to protect the earth's oil reserves. This is why we at VAUDE also use post industrial recycled polyamide.

From bottles to bags: PET recycling

Another source material for recycling at VAUDE is used PET bottles. These are collected, purified, ground and processed to form granulate that is then melted and spun into yarn.

The benefit of this kind of recycling is twofold: about 80 million tons of plastic packaging are produced annually. Of this, 32 % ends up in the environment. PET bottles and other packaging make up a large portion of this. From an ecological standpoint, it makes absolute sense to reduce these mountains of plastic.

In the process, high-quality polyester is produced, which in its manufacturing requires 50 % less energy and produces approx. 50 % less CO₂ emissions . Absolutely no fossil fuel petroleum is required.

|

The Recycling Cycle

Collect, clean, granulate and spin: the recycling cycle of PET bottles. Water-resistant products such as bags and backpacks are made using the fibers that result from this cycle. |

Fully functional. Duly delightful. Polyester recycling

For some of our highly functional products we include recycled polyester. These are material surpluses from polyester production, which - instead of being disposed of as waste, as is often the case - are collected and returned to production. This conserves resources and still provides our products with full functionality.

The process involves recovering the distinct polymers that make up the synthetic fiber and reassembling them.

This produces a granulate that can be spun into yarn and woven to make fabrics. This reduces landfill waste, as these materials are recycled rather than disposed of. There is no additional need for petroleum in the reclamation of these polymers.

Our coffee to go

One of our favorite materials is S.Café® recycled polyester. This material involves a spin mass made from recycled, melted polyester granulate that is mixed with used coffee grounds.

The material is partially biobased, dries fast, provides UV protection and has the bonus effect of being antimicrobial, which prevents odors and allows us to eliminate the use of chemical anti-odor finishes. This is a great thing and it is why we are using this material in T-shirts, jackets, fleece products and chamois for bike shorts.

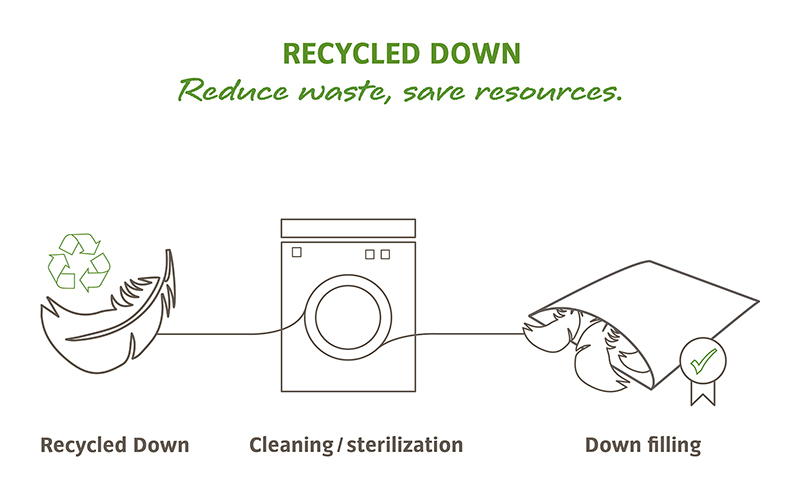

Recycled Down

It’s not just synthetic materials that can be recycled. In the Summer Collection 2019, we also used 100 % recycled down as insulating fill for our sleeping bags. You can find more information about it here.

Increasing percentage of the Collection

VAUDE wants to continue to promote the use of recycled materials so we have raised our requirements within the VAUDE Green Shape label for the Summer Collection 22 – a product must have at least 50 % recycled weight content to earn the Green Shape label.

More information about the Green Shape criteria can be found here.

You can check the exact recycled content of your product directly in the care label or in the material overview in our online store.

Percentage of products made from recycled materials

Create your own infographicsNotes on this graphic:

- “Total” refers to all backpacks, bags and bike bags from the product areas Mountain Sports, Bike Sports and Packs ’n Bags.

- The following applies to all products: the percentage of all integrated primary materials made from recycled materials is at least 30 %. When the percentage of integrated recycled materials is significantly higher, the products have the VAUDE Green Shape label. This representation differentiates based on the percentage of recycled materials, but not whether the product has or doesn’t have Green Shape status. Green Shape concerns very different sustainability criteria. Read more here.

Certified Recycled Materials

All recycled textiles used by VAUDE meet the following standards:

Since 2020, VAUDE itself has been certified by the Global Recycling Standard (GRS). You can take a look at our certificate here. This certification allows us to verify the recycled content of a product and track it along the production chain. In addition, the GRS standard covers guidelines on environmental management and corporate social responsibility.

In order to label a product with the GRS logo, each production step must be certified. Starting with the raw material supplier, through the yarn supplier, the knitter or weaver, the dyer and laminator, to the garment maker and finally to us as a retailer.

Some of our material suppliers are already certified, but we are not yet allowed to label our product with this information. We are currently working on defining product areas in which we can certify the production chain in order to be able to label these products with the GRS logo.