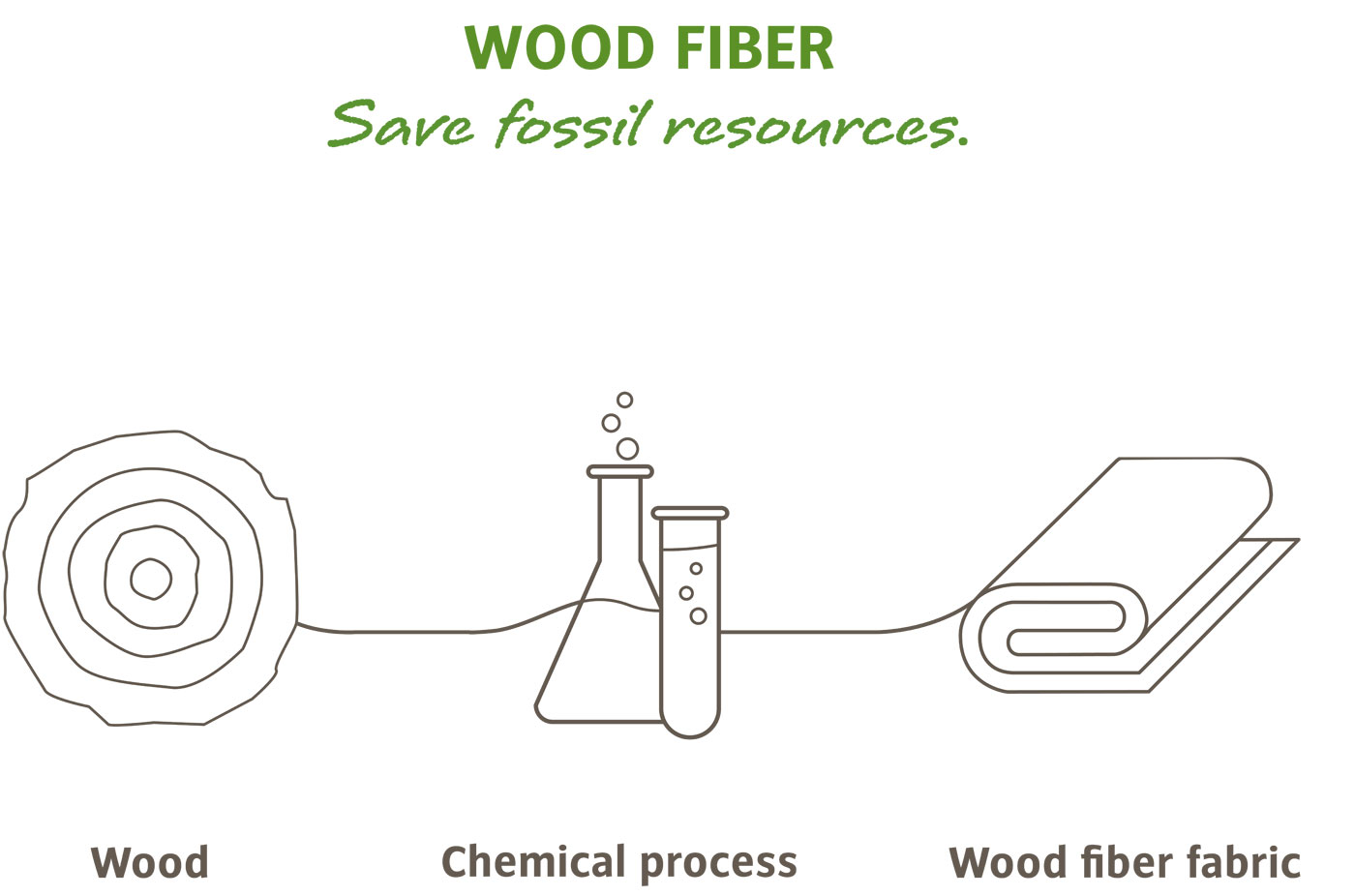

Making clothes from trees

Simply wood – simply good.

For many VAUDE products, we use a celluose fiber made from 100 % certified sustainable wood that’s 100 % biodegradable.

Cellulose fibers have moisture management characteristics, feel soft against the skin and ensure cool microclimate. They are used to make a fabric that’s very eco-friendly thanks to its resource-conserving, closed loop production cycle. Wood you wear it?

Wood for clothing, reducing microplastics in our seas

VAUDE was the first outdoor outfitter to develop a soft and cozy fleece made with cellulose fibers. Microfibers that are washed out of fleece fabrics and enter the water cycle is fully biodegradable in seawater and inland waters. This fabric is helping us prevent damage to the planet and marine life.

We began using this innovative fabric construction for various models in our apparel collection in the Summer 2019 Collection. Read more about it here

Fibers made from cellulose: silky smooth, breathable and environmentally friendly

Cellulose fiber has many beneficial properties and is comfortable to wear. Record quantities are being produced every year and there is currently no end in sight to the rush for cellulose fibers. Sales for this cotton-like fiber are lucrative and there are more and more manufacturers producing this eco-friendly viscose.

The source for this fiber is wood pulp. In some cases, the type of wood is specified by the manufacturer. It is important to us that the wood for our cellulose fiber comes from sustainable forestry, which is why we only use FSC-certified Lyocell.

Conventional viscose is produced in a chemical process. In very simplified terms, the solid pulp is liquefied with the aid of chemicals to produce a spinning mass, which is spun out into filaments and cured with the aid of additives. The process can involve questionable chemicals that are not always monitored in the manufacturing process and sometimes even end up in the environment. That's why VAUDE only uses Lyocell. From an environmental point of view, this offers several advantages:

- Lyocell fibers are produced in a non-chemical process that uses an environmentally friendly solvent

- Lyocell is produced in a closed production cycle. This reduces emissions to a minimum. Solvent and water are completely recovered and reused in the process

- In addition, the lower water and energy consumption compared to the production of conventional viscose is another advantage

- Lyocell is biodegradable

Naturally inhibited bacteria growth

Cellulose fibers are used to make materials with a silky-smooth surface. In outdoor apparel, this fabric transports moisture quickly and effectively away from the body, which keeps you cool and comfortable.

The fabric does not require additional anti-odor chemicals to ensure the product’s high functionality, as bacteria growth is inhibited by the material itself so that odor build-up doesn’t occur.