Microplastics in the world’s oceans

More plastic than fish

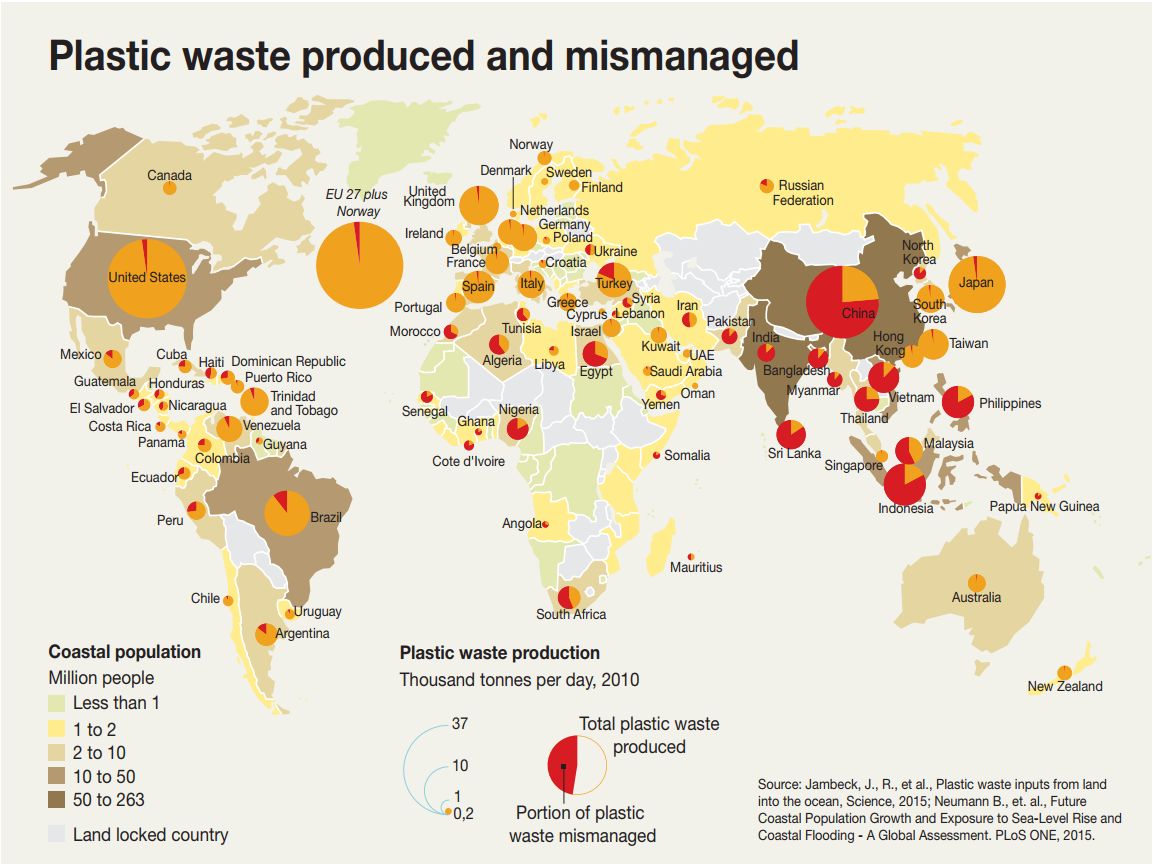

Experts estimate that up to 12 million tons of plastic garbage is landing in our oceans every year. And even though our "western" industrialized world is clearly producing too much plastic, at least most European and American industrialized countries have reasonably functional waste disposal systems.

In Asia, on the other hand, infrastructure for collecting plastic and recycling it appropriately – if only as fuel for the production of electricity or heat – is often fully lacking.

Source: http://www.grida.no/resources/6931 (englisch)

Because our main production countries are in Asia, we are also responsible and have to do our part to help solve the problem. We are working to raise awareness among our suppliers for the issue and we want to support our partner, the WWF Germany in building a network of waste management systems in the Mekong Delta.

Microplastics - miniature particles do maximum harm to the environment

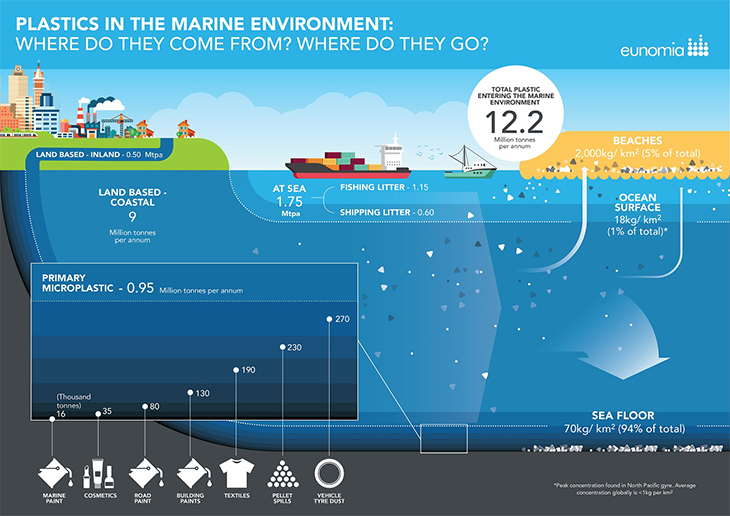

In addition to the larger pieces of plastic waste entering the waterways where they decompose very slowly, we as an outdoor brand have a particular problem: tiny fiber particles that are shed from our products and are too small for normal filtering in sewage treatment plants are entering the oceans as microplastics.

Because our products are usually made of synthetic fibers such as polyamide or polyester, we are unintentionally contributing to pollution in the oceans as well.

What makes microplastics so tragic is that not only are they extremely durable and take hundreds of years to decompose, they also don’t generally float at the top of the ocean but rather somewhere between the surface and the sea floor. Marine animals mistake them for food and end up starving with their stomachs full of plastic. As a part of the food chain, these plastics accumulate in larger animals and also end up in the food we eat.

Source: http://www.eunomia.co.uk/reports-tools/plastics-in-the-marine-environment/

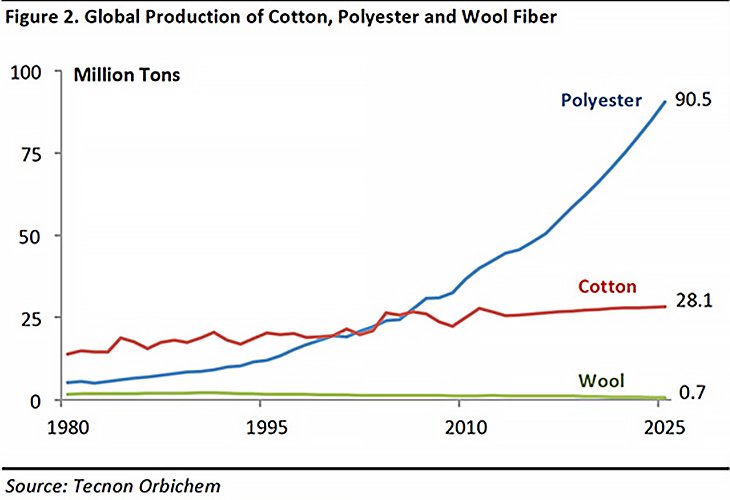

Worldwide production of synthetic fibers is growing rapidly

As a manufacturer of outdoor products, we also use the many advantages and functional properties of synthetic fibers such as polyester and polyamide. Globally, the production of synthetic fibers is rising significantly. This means that more plastic in the form of textile fibers is entering our environment every year.

Innovations in Fabric Materials

Tackling the problem at its source

Of course, we are concerned that our products are polluting the environment with microparticles. We want to tackle the problem at its roots: in the materials that we use. Either these materials shouldn’t shed any microfibers at all or what they do shed should be biodegradable... without any loss to functionality of course. We have already found some promising initial approaches that we are testing.

We initiated a major research project to make joint progress in this area. VAUDE was actively involved in the consortium project "TextileMission" from September 2017 to March 2021. The aim of the research project was to reduce the environmental impact of microplastics that textiles made of synthetic fibers shed during household washing.

"TextileMission" was funded by the German Federal Ministry of Education and Research (BMBF) under the funding priority "Plastics in the Environment - Sources, Reduction, Solutions" with a budget of 1.7 million euros.

The following organizations from the sporting goods industry, the washing machine and detergent sectors, research and environmental protection will contribute their respective expertise to the project as project partners:

- adidas AG

- Bundesverband der Deutschen Sportartikel-Industrie e.V. (National Association of the German Sporting Goods Industry, BSI) as the project coordinator

- Henkel AG & Co. KG

- Hochschule Niederrhein - Faculty of Textile and Clothing Technology

- Miele & Cie. KG

- Polartec LLC

- TU Dresden

- WWF Germany

In Focus: Textile production and sewage treatment technology

TextileMission pursued an interdisciplinary research approach that focused primarily on two solutions. The first is that textile technology research and the optimization of production processes were to be used to develop textiles that shed significantly less microfibers than previously. In the process, we worked together with textile researchers from the Niederrhein University and our cooperation partners Adidas and Polartec to develop environmentally friendly alternatives.

Secondly, TU Dresden worked on optimizing wastewater treatment plant technology and developing a filtration system in cooperation with industrial partners Henkel and Miele. With the help of this improved technology, washing tests at the Niederrhein University of Applied Sciences made it possible to systematically collect data on the extent and range of microparticles shed from different textiles.

Research was supported by the holistic evaluation of solution strategies from a nature conservation and environmental perspective by WWF Germany and the scientific support and public relations work of the Bundesverband der Deutschen Sportartikel-Industrie e.V. (Federal Association of the German Sporting Goods Industry).

International Textile Mission Final Conference

Central topics were:

- Causes and extent of microplastic loss in textile

- Development of low-emission textiles

- Biodegradable plastics as alternative fiber materials

- Textile recycling and the circular economy

- Retention of textile microplastics in sewage treatment plants

Our current fleece products with solutions for eliminating the use of microplastics were also exhibited and discussed. First and foremost, the TENCEL® fleece made from cellulose fibers which are obtained from eucalyptus or beech wood.

However, in order to reduce the microplastic input through textiles, solutions for reducing fiber loss also need to be found in the field of synthetic fibers. For this reason, TextileMission is continuing its work on both approaches.

A detailed summary of the conference can be found here.

Opening of the TextileMission Conference in Berlin, November 2019

Photo: Esteve Franquesa

First results: Environmentally friendly care and maintenance also reduces fiber loss

As a partner of the TextileMission project, we made some of our products, especially fleece jackets, available for washing tests. The washing machines and tumble dryers at the Niederrhein University of Applied Sciences ran at top speed for months to investigate the factors influencing the fiber loss of textiles.

The first results show a higher particle output in the tumble dryer than in the washing machine. In addition, it has become clear that the loading of the devices has a decisive influence on fiber loss. Loads of 1.3 kg and 3.2 kg during washing and drying were compared.

This clearly shows that a heavier load has a positive effect on fiber loss. This means that with a larger load, relatively fewer particles are carried into the environment. As a result, optimum utilization of the washing machine and dryer (according to the manufacturer's specifications) is not only worthwhile from an energy point of view. In addition, we can all make our own contribution to reducing the particle output of textiles.

You can find an overview of all environmental tips for laundry here

Relative fiber release from washing and drying depending on washing load

Create your own infographicsCollaborative cooperation for the development and implementation of test procedures

To be able to transfer our research results to a broad industrial scale, we became a member of the Microfiber Consortium in January 2020. This association, consisting of companies from the textile industry and research partners, serves as an exchange platform and framework for better understanding and learning how to avoid fiber loss in textiles.

| GRI: | 103 |

| GRI: | 306-5 |