Synthetics from renewable resources

Forward to nature

VAUDE uses synthetic materials such as polyester, polyamide or polyurethane for many of its products. These materials are derived from petroleum.

We have set ourselves the goal of increasing the amount of renewable raw materials we use. In this way, we can use less fossil fuel-based resources and avoid adding more plastic to the planet.

Our concrete objective is:

By 2024, 90 % of all VAUDE products will have a recycled or biobased material content of more than 50 %.

Animal-based, plant-based, recycled, biobased

Renewable resources can be natural plant fibers such as organic cotton, hemp or kapok. Animal-based raw materials such as down, merino wool or leather can also be an alternative to synthetic materials. Fibers from cellulose are also suitable, such as fibers from wood, a renewable resource. Read more here

In addition to the use of renewable raw resources, we are focusing on using materials from existing closed loop cycles and breathing new life into them. This helps us to conserve valuable resources by using a variety of recycled materials in our products. Read more here

Coffee grounds for waterproofing

We have managed to substitute fossil components with biomass in our Ceplex Green membrane.

With this innovative technology, up to 25 % of conventional polyurethane is replaced by s.Café®. The biobased material is obtained from recycled coffee grounds and then processed in our highly functional Ceplex Green membrane.

Read more here

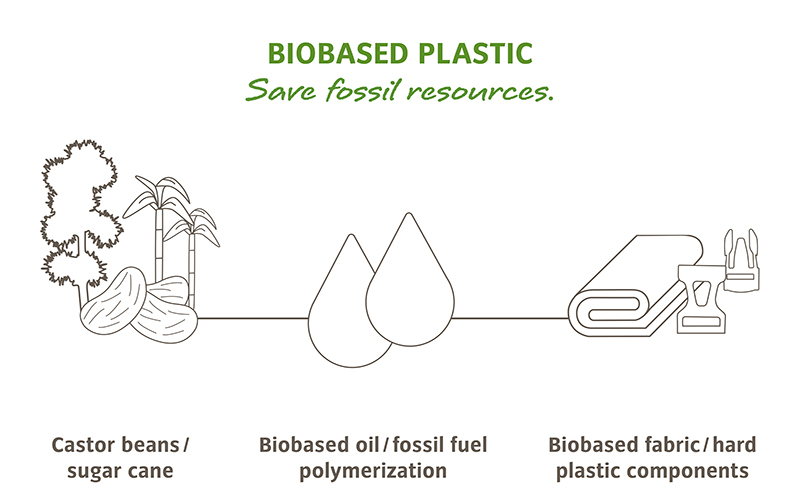

Zips made from castor oil

We have also been using bioplastics for hard plastics and textiles since 2018. Using polyamides with a renewable content of over 2/3, this biobased content comes from the oil of the castor plant.

The robust castor plant grows without additional irrigation on barren soils that are unsuitable for growing food. The oil is pressed from the plant’s beans and can be used to make textiles as well as plastic components such as zips and buckles.

»The castor bean plant doesn't require fertilization or artificial irrigation, grows in dry areas that aren't suitable for other types of agriculture in the first place - and is a popular food for caterpillars but inedible to humans and other mammals. The oil is made from the seeds, but unlike the seeds is completely non-toxic. «

Bioplastics for durable products

We can reduce the need for fossil resources by using materials from renewable resources.

Bioplastics can have a wide variety of properties: either equal to or even better than those of conventional plastics, for example lower weight or better impact strength.

We are continuously working on bringing new bioplastics to the market and using them in our industry. The EFFECTIVE project gives an indication of this. In this ambitious project we are developing the world's first biobased polyamide 6 together with international partners. You can find information about this project here.

Criteria and trade-offs

Clearly renewable resources are a good option. Unfortunately, there are a few pitfalls that need to be avoided.

We think that it is important to avoid any conflict between cultivating agricultural raw materials (such as corn) and the production of food. This is difficult to ensure. At the moment, our decisions are based on the location of the growing region and the living standards of the local population.

Due to the high level of public attention on genetic engineering and the current relevance for us with regard to the production of biobased plastics, we at VAUDE have taken a close and nuanced look at this issue.

Genetically modified plants, which are already being cultivated in many regions of the world (and in some cases on a significant scale) can have incalculable effects on their surrounding environments, ecosystems and the region’s biodiversity. Even though many of the possible risks have been only slightly or not at all proven in previous studies, the use of certain pesticides, for example, has been greatly increased by the use of pesticide-resistant plants. Due to the unpredictable and, at times, difficult to control effects of these organisms on their environments, we reject the use of this type of genetic engineering at VAUDE and do not use any materials generated by or derived from genetically modified plants or animals in our products.

Genetically modified microorganisms in closed fermentation processes, on the other hand, enable the production of biobased plastics with a higher efficiency and yield. This improves the ecological balance of biobased plastics production. In other words, they are providing a vital function in order to avoid the use of limited fossil resources and to use renewable resources as raw materials.

If microorganisms have been generated exclusively for use in contained systems and are not viable outside these systems, the use of these microorganisms does not pose any risk to humans or the environment. From this perspective, the use of these microorganisms appears to make a meaningful contribution to the development of biobased plastics and to improve their ecological balance.

We in the VAUDE CSR-Team have hotly debated one exception.

Two shoe models that made their debut in the 2018 Summer Collection include a biobased TPU in the heel counter and toe cap. This innovative material is made from 50 % renewable raw materials and is characterized by a high abrasion resistance and low weight. Currently however, this material is only available in a form that includes a proportion of genetically modified crops.

In this particular case, we decided to make an exception to our Green Shape exclusion criteria. We are working diligently to find a GMO-free alternative for this material.

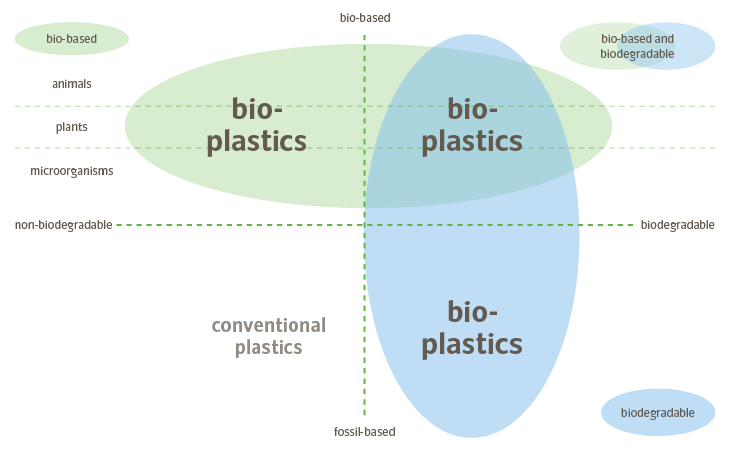

Biobased or biodegradable

Synthetics that are made from renewable resources rather than petroleum are highly innovative. Frequently, these types of bioplastics are equated with “biodegradable” or “compostable” – but this isn’t always the case. Many biobased synthetics have exactly the same properties as conventional plastics. This usually includes their low biodegradability. By the same token, there are also conventional, petroleum-derived plastics that are biodegradable. This means that the origin of the material, whether it’s biobased or petroleum-based, is independent how biodegradable it is.

You can find out more about the biodegradability of plastics and other materials Synthetics that are made from renewable resources rather than petroleum are highly innovative. Frequently, these types of bioplastics are equated with “biodegradable” or “compostable” – but this isn’t always the case. Many biobased synthetics have exactly the same properties as conventional plastics. This usually includes their low biodegradability. By the same token, there are also conventional, petroleum-derived plastics that are biodegradable. This means that the origin of the material, whether it’s biobased or petroleum-based, is independent how biodegradable it is.

You can find out more about the biodegradability of plastics and other materials here.

| GRI: | 301-1 |