Suppliers as partners

Environmental Stewardship Program for Suppliers

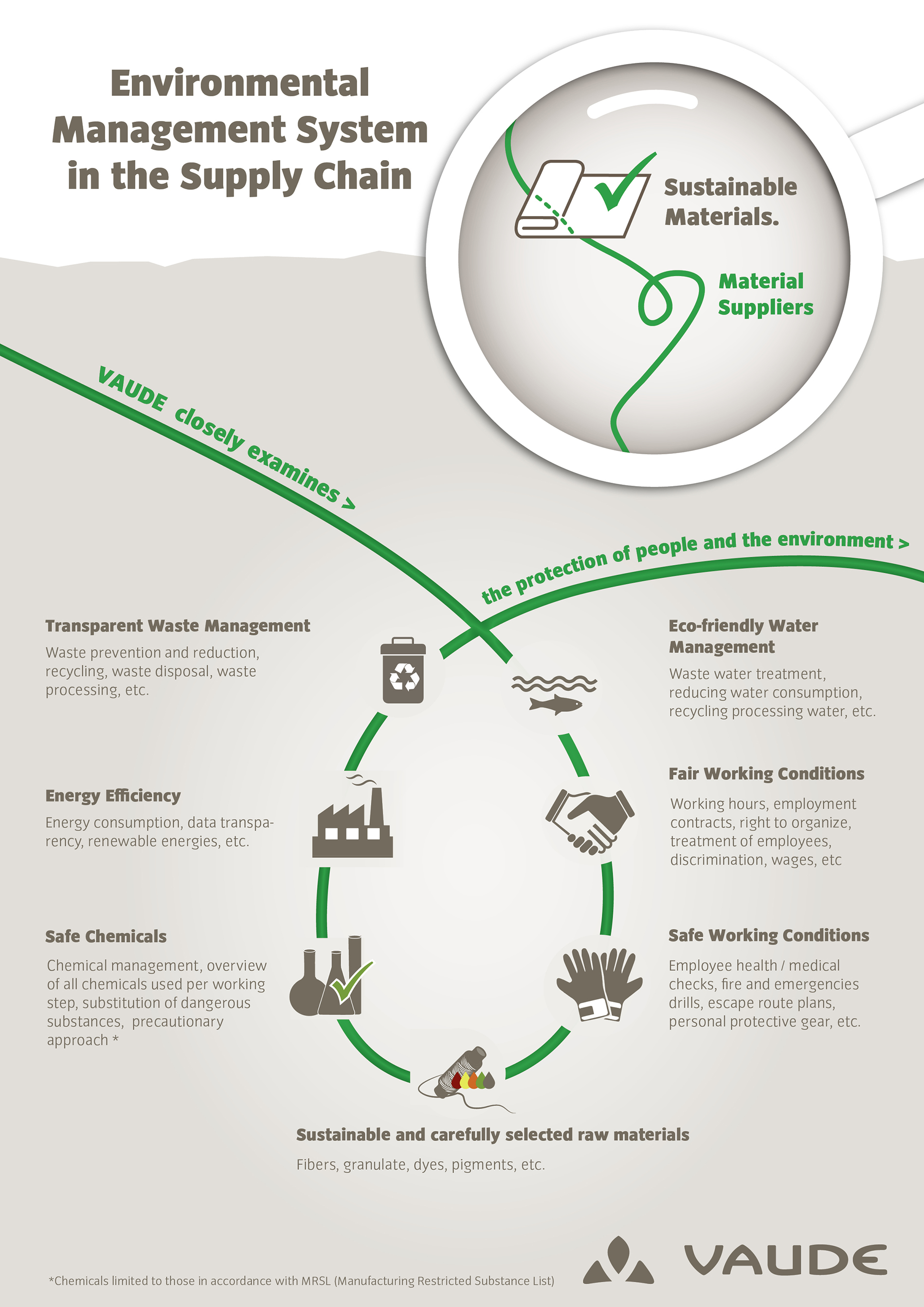

VAUDE is also consistently moving towards more sustainability through sensitization, training and support for Environmental Management in the supply chain. In this area, we have already done a great deal of pioneering work in the industry and are on the right track. Background and details here.

Material manufacturing is often ecologically problematic

VAUDE differentiates in its supply chain between producers (manufacturers of ready-made clothing, Level 1) and material suppliers (Level 2). We only have a direct (contractual) business relationship with our producers. However, we stipulate the selection of material manufacturers to a large extent – see Our Supply Chain

In production, the materials are then assembled to form the VAUDE finished product (sewn, HF welded, etc.). This, of course, consumes energy, water and chemical additives, and causes waste, waste water and emissions.

Pilot project for a higher level of environmental protection

However, the most serious environmental impacts occur at the upstream stages of production: the manufacturing of textile materials and even further upstream to the cultivation of plant fibers or the mining of raw materials such as oil, from which synthetic fibers are obtained.

These production steps are very resource intensive. The consumption of water, energy, materials and chemicals, as well as emissions such as waste water and exhaust have a major impact on the environment and the people living there.

Focusing on a higher level of environmental protection

Despite our current high standards, there is still much room for improvement in environmental and resource protection, in compliance with international environmental standards and the implementation of a systematic environmental management.

As a founding member of the federal government’s "Alliance for Sustainable Textiles" VAUDE is setting a good example and heading in the right direction:

In collaboration with the Federal Ministry of Economic Cooperation and Development (BMZ) VAUDE launched the project "Environmental Stewardship in the Textile Supply Chain" in 2015. Within the framework of the Deutsche Entwicklungsgesellschaft DEG, which promotes the “develoPPP.de" program, VAUDE supports material suppliers in introducing sustainable systematic environmental protection and in continuing to improve the measures they already have in place.

More details on the project

The goal of the project is to raise awareness and the empowerment of selected VAUDE material suppliers in Asian procurement markets (e.g. Vietnam, China, Taiwan), so that they can more easily meet our environmental requirements.

Companies and their employees receive practical assistance for the autonomous implementation of measures in the area of corporate environmental and sustainability management – helping them to help themselves, so to speak.

We want the companies to recognize what advantages they have from clean production: healthier employees, higher product quality, better life conditions in the region, and last but not least, a reference as a qualified producer for international competition, which can be used for winning new customers.

Best Practice examples of participants and discussions with experts help to establish practical relevance for the facility and allay reservations for the participants.

How does the project work?

- Taking stock with supplier self-assessments and evaluation by VAUDE using external experts

- Selection of ten pilot suppliers

- The creation of assistance and training materials (documents in local language, graphics, explanatory films)

- Implementation of training and individual consultations on-site in the local language

- Evaluation and anchoring of the results in the respective facilities, including responsibilities distributions and monitoring systems

- Promotion and strengthening of synergies through networking of suppliers among each other and with external experts, publication of findings from the project.

The project is very ambitious and scheduled for 2 years. Upon completion, the approach should be extended to the entire supply chain. We will regularly report on progress and results here.

Committed to compliance with standards

All VAUDE producers are contractually obligated to comply with ecological minimum standards. This includes, among other things, the Restricted Substance List - RSL.

With the internal VAUDE Material Policy, we gather a pre-selection of materials and technologies which we use to influence the selection of our material suppliers. Because of the system partnerships that many of our material suppliers have with bluesign® and the Fair Wear Foundation (FWF), we have a deep understanding of the situations, weak points and potential for development of most of our producers and material suppliers.

Selection and evaluation of VAUDE producers subject to a well-thought-out process that follows strict criteria (see also Complex Supply Chain.)

Find out more at:

| GRI: | G4-EN32 |

| GRI: | G4-EN33 |

| GRI: | G4-DMA Supplier Environmental Assessment |