Production in Myanmar – Loyal Partnership

Why does VAUDE produce in Myanmar?

Our partner began operating in Myanmar in 1999 – at that time primarily for the American market. After the US embargo came into effect in 2003, this producer approached us and asked if we were willing to support his production in Myanmar. Due to the embargo, our partner had existential problems and badly needed new customers. In order to maintain jobs there, VAUDE decided to produce in Myanmar as well in 2003. Since that time, we have produced specific products in this factory in Myanmar. Myanmar is classified as a high risk country by the Fair Wear Foundation (FWF).

Today, the factory in Myanmar has nearly 2000 workers. VAUDE’s orders make up about 44% of the total capacity. The factory in Myanmar accounts for about 14% of the total turnover amount of all VAUDE product groups.

FWF Audit in Myanmar

VAUDE has been a FWF member since 2010. From the beginning, it was important to us to have the factory in Myanmar audited. Because the FWF there did not have a complete network, VAUDE had the factory audited in November 2014. The audit was implemented by the FWF, with auditors who speak the local language.

During the audit, there were a few discrepancies that were summarized for corrective measures. Subsequently, we worked together with the producer to establish and define remedial action.

At the end of 2016 the FWF will implement a verification audit and, if necessary, identify the points that still need to be improved.

2014 Audit Results and Status quo

| Working Standard | Discrepancy | Status quo |

|---|---|---|

|

Grievance system |

There is no system in place for complaints and grievances. Workers must be informed and educated about the complaints procedure. Every complaint should be responded to and the outcome should be documented and made known to workers. |

The production facility implemented a grievance system. |

|

Communication |

The workers are not well informed nor are they aware of the FWF Code of Labor Practices and/or relevant national or local legislation. |

We implemented WEP Training in which the workers were trained on the CoLP as well as national and local legislation. |

|

Communication |

The workers received neither an introductory program nor a training plan. |

In progress |

|

Discrimination |

The factory does not have a written policy regarding discrimination. |

Guidelines regarding discrimination were created and communicated. |

|

Freedom of association and the right to collective bargaining |

There is no record demonstrating regular meetings between the employer and the union/workers representative. |

In progress |

|

Payment of a living wage: |

There were several discrepancies here:

|

|

|

Working hours |

|

|

|

Safe and healthy working conditions |

We found several discrepancies here:

|

Most of the discrepancies relating to work safety have been remedied. However, a systematic work safety management system needs to be implemented. We are supporting our producers with on-site visits as well as participation in trainings. |

|

Legally binding employment relationship |

The factory does not provide a contract to all workers. |

In the future, all workers will have a contract. |

Continuous support for improvement processes

The VAUDE CSR team provides ongoing support to production facilities for the implementation of corrective actions. As a holistic understanding on the issue of labor standards and CSR is lacking, this producer was intensively supported by the CSR team and visited several times during the year. In a multi-day on-site visit by Susanne Medesi (VAUDE Manager of Central Purchasing / Production & CSR) and Anika Rudolf (VAUDE Associate CSR) all discrepancies were intensively monitored and remedial measures were jointly established. Here one could clearly see that there is a will to work on the discrepancies, but unfortunately the knowledge for implementation is often lacking. For this reason, we have agreed with our producers on a variety of qualification measures.

Training & Capacity Building as a key to improvement

In 2015, our producer took part in a fire safety training as well as HR Management System Training. In addition, the management and workers participated in training within the scope of the WEP (Workplace Education Program) in November 2015. This year, our producer will participate in the Compliance Academy of SMART and be mentored over several months by SMART. The aim of the Compliance Academy is to improve the management system of the production facility and to anchor strategies and processes in order to achieve good long-term working conditions. During the program there is group training as well as on-site consultations.

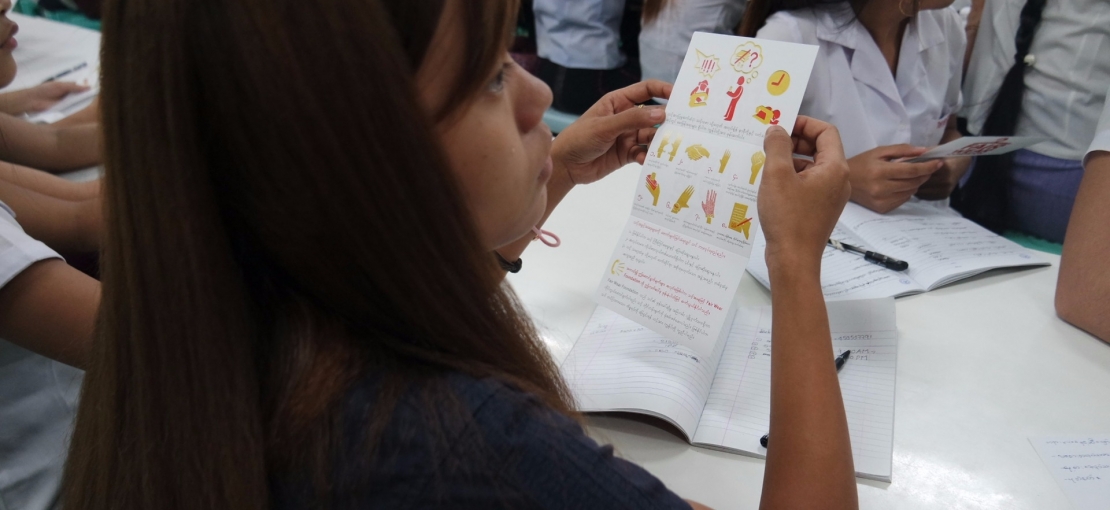

WEP Training in Myanmar

Due to a lack of local partners, the FWF is not active in Myanmar at the moment. But, it was important for VAUDE to offer the producer and its workers a "Workplace Education Program" (WEP). For this reason, VAUDE decided to organize a WEP itself. This training project was implemented together with two other FWF members. The training course was based on the "Workplace Education Program" (WEP) of the FWF. The first task was to find a local partner.

After intensive discussions with SMART and an on-site visit, it was clear that they were the right partner for the preparation and implementation of the training. The manager of SMART has many years of experience in the fields of CSR and labor standards and also an in-depth understanding of the country. In preparation for the training, laws and regulations were researched and training materials were developed. The knowledge of the trainers regarding local regulations and laws was extremely valuable. Two training courses were prepared and implemented. One course was specifically aimed at the workers; the other was for the executives of the production facility.

Both courses included training on labor standards and information on the applicable laws in Myanmar.

The complaints procedure was also explained in detail (details here). An important focus was on communication between the management and the workers in the production facility, because well-functioning internal communication is crucial for compliance with the essential requirements of CoLP and improving working conditions in the long term. The training was carried out in November 2015. The feedback from the managers and the workers was very positive.

Complaint hotline in Myanmar established

Within the scope of the WEP training, VAUDE, together with two other FWF members, established a complaint hotline in Myanmar; as yet, there is no FWF Complaint System there. For VAUDE, it was important that the workers of the Myanmar production facility have the possibility to address complaints to a neutral body on occasions when problems cannot be solved within the company. SMART is also our partner here, acting as the local complaints manager. If a worker complains, SMART passes the concerns on to the FWF who then discusses the issue with VAUDE. In the next step, the complaints are then dealt with in accordance with the FWF complaint procedure.

The complaint hotline has been active since the end of November 2015 – so far no complaints have been received.

We have made all the expertise that we gained in Myanmar – both the training materials as well as information on the complaint hotline – available to the FWF. FWF members who produce in Myanmar and need information, contacts, or training materials can rely on our resources.

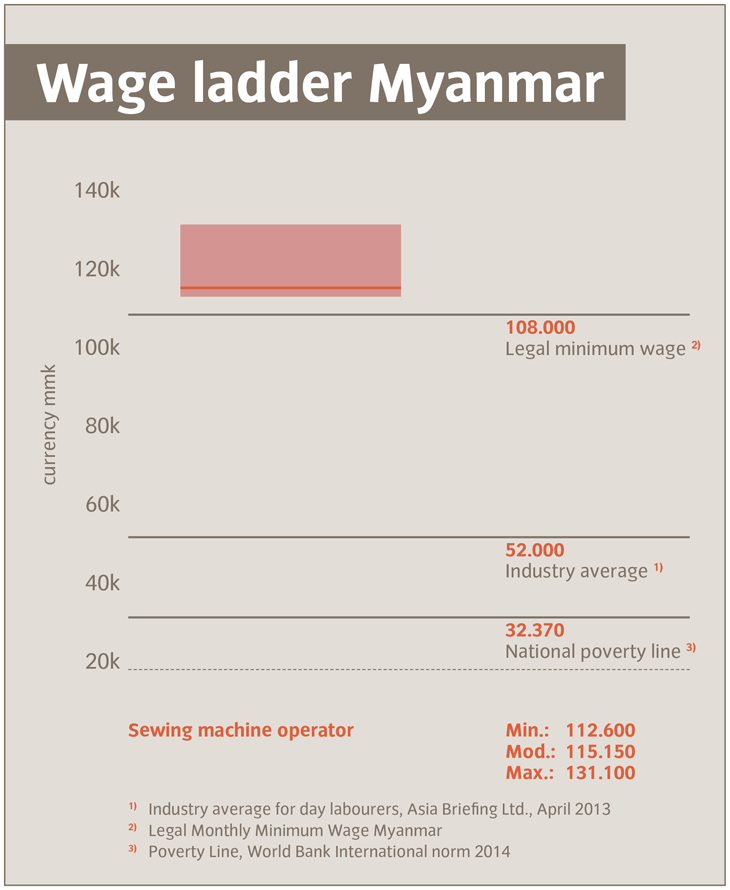

Important progress – introduction of minimum wages

An appropriate legal framework with respect to labor standards continues to be lacking in Myanmar. Important progress was made with the introduction of a minimum wage, which became valid in September 2015. The newly introduced minimum wage is 3,600 kyat per day for an 8-hour shift. Because there is no AFW calculation of a living wage for Myanmar, our VAUDE CSR staff gathered wage figures during an on-site visit in November 2015 and created a Wage Ladder based on this data. Using the Wage Ladder, our producer’s paid wages were compared with the existing benchmarks of the FWF. We found that wages at our production facility are not only above the minimum wage; they’re also higher than the average wages for the textile industry in Myanmar.

Wages illustrated show the regular wages including overtime, bonuses and special payments.

| GRI: | G4-LA15 |

| GRI: | G4-HR11 |