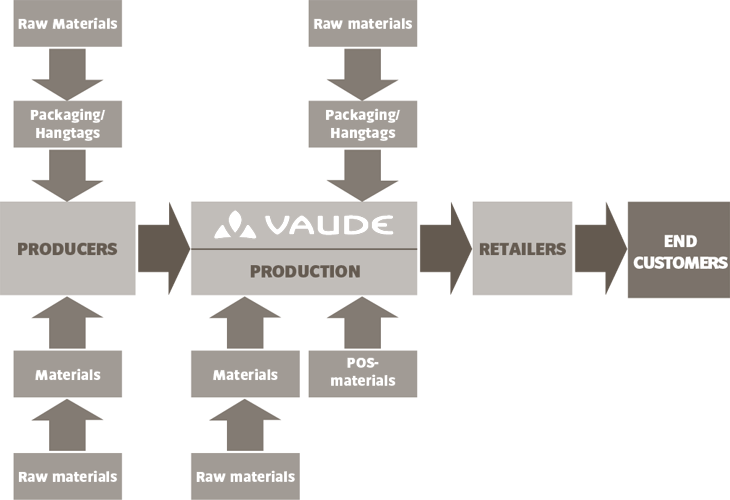

Complex supply chain

Production in Europe and Asia

VAUDE develops, manufactures and sells outdoor equipment such as performance apparel, backpacks and bags, shoes, sleeping bags, tents and camping accessories. The supply chain of outdoor products is complex, covering a wide international network and entails numerous potential ecological and social challenges.

We recognize our responsibility for the conditions under which VAUDE products are manufactured worldwide. We accept this responsibility as a permanent challenge in a globalized market. This concerns not only ecological aspects, but also social standards.

How we ensure high social standards for our production in Asia is described here.

High environmental standards in our production facilities is just as hard to implement as it is important. Find background information and details on what VAUDE is doing here.

VAUDE supply chain and value chain

Our direct business partners for product manufacturing are our producers: clothing manufacturers (also referred to as Tier 1) – the first VAUDE upstream level in the value chain. These companies manufacture finished VAUDE products from selected materials.

Supply chain from resources to consumers

Labour-intensiv textil industry

In general, the textile and clothing industry is very labor intensive. In the outdoor industry, the highly sophisticated and complex products manufactured generally require qualified personnel and modern machinery.

We require durability, highest functionality and quality from our products, and that they are made from materials that are as sustainable as possible. That is why we work closely with our producers and get involved in the selection of a majority of material suppliers as well. More at Suppliers as Partners

Partner-based relationships: we work on the environmentally friendliness of our products in collaboration with our producers.

Number and location of suppliers

In 2015 about 5 percent of our sewn products (measured by the overall expenditure on products) were produced with climate neutral manufacturing at our company headquarters in Obereisenbach. You can find more information about our Made-in-Germany Collection here.

Most of our products are made by external contractors and distributed by VAUDE. VAUDE traditionally cultivates business partnerships and always works directly with its producers. The majority of our 52 producers have their manufacturing facilities in China and Vietnam.

More information, how VAUDE works on social standards in the production, can be found here.

Material manufacturing

The second VAUDE upstream level of the value chain (“Tier 2”) are the fabric/materials producers who make items such as woven or knit fabrics.

To do this, they purchase fibers and components such as dyes – from other suppliers. The woven or knit fabric is then “finished” with chemically or mechanically processes such as dyeing, laminating, applying substances for UV protection and water resistance. The yarns are made from fibers or synthetic granulate.

It takes about two years between the time that we design a product until it is manufactured. Short-term changes in the supply chain often bring along difficulties in the coordination with regard to quality and environmental or social standards .

Careful selection and evaluation as well as partnership-based collaboration with our producers is therefore important to VAUDE, not only for environmental reasons but also to ensure product quality – for instance with regard to the management of harmful substances.

Primarily nominated material suppliers

For the majority of its products, VAUDE specifies which materials (such as fabrics, buttons, rivets, buckles, as well as packaging materials and labels) that suppliers should use and in which quality. In total, VAUDE has nominated about 150 of these material manufacturers.

Our producers sometimes rely on local suppliers, especially for small components such as thread. We cannot summarize the exact number of local suppliers. However, all of our producers agree to comply with the VAUDE quality criteria including hazardous substances limit values for all materials used.

Number and location of our material suppliers

Most of VAUDE material suppliers have their headquarters in Asia, especially in Taiwan, China and South Korea. But we also have material suppliers from Europe, for example from Germany, Italy and Switzerland. For the on-site production in Obereisenbach, we have around 38 suppliers – 27 from Europe and 12 from Asia.

High product safety with the bluesign® system and Fair Wear Foundation

VAUDE has worked with most producers and material suppliers for years. We evaluate producers systematically in accordance with the following criteria

- Product quality

- Delivery times

- Production amounts in quantity and turnover

- Fair Wear Foundation Audits

- Management of harmful substances

With the bluesign® system and the Fair Wear Foundation (FWF), we achieve a high standard of safety in our supply chain.

Systematic evaluation system in construction

A standardized evaluation system for the consistent evaluation of all producers and material suppliers in relation to environmental aspects is under construction.

Our goal is not only complete transparency of the origin of all materials processed by VAUDE throughout the various upstream stages of the supply chain, but also a complete evaluation system for producers and suppliers. Some prerequisites for this have yet to be created - such as the transparency of data on energy and water consumption.

| GRI: | G4-12 |

| GRI: | G4-13 |

| GRI: | G4-EN32 |

| GRI: | G4-EN33 |