Complex products, global supply chain

Production in Europe and Asia

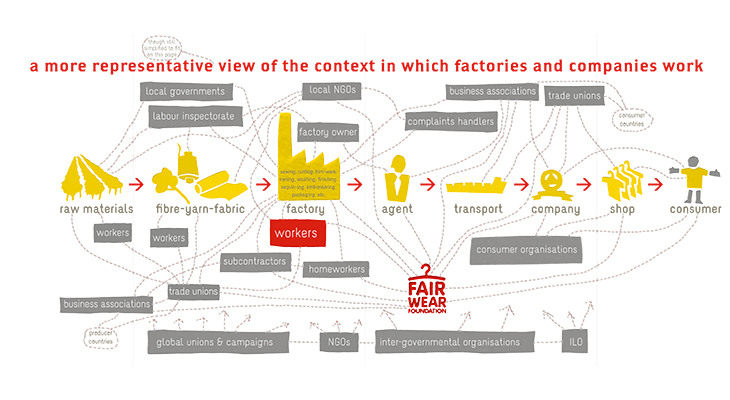

The supply chain of our products is complex, international, and has many ecological and social challenges.

You are quite right to expect us to assume responsibility for the conditions under which your VAUDE product is manufactured. And this also goes for ecological and social issues, from the raw material to the production of the fibers, yarns and fabrics to the finished product.

Graphic: Fair Wear Foundation

Clothing manufacturers: cut – make - trim

Our direct business partners for product manufacturing are our producers. They prepare the fabrics, cut out pattern pieces and sew them into finished products. Quality control and packaging finish off the process.

In general, the textile and clothing industry is very labor intensive. The manufacturing of our VAUDE products is very demanding. Many people work on many sewing machines – of course we need to ensure fair working conditions. Read more here to find out how we put this into practice.

All VAUDE producers are obligated to the follow the VAUDE quality criteria including the Manufacturing Restricted Substances List (MSRL) for all materials they use.

Where are VAUDE products made?

In 2016 about 5% of our sewn products were made at our climate neutral headquarters in Obereisenbach (measured by sales value of the products). Find information here about our Made in Germany Collection.

The majority of our products are manufactured by external contractors and distributed by VAUDE. VAUDE cultivates traditional, partnership-based business relationships and always works directly with its producers. The majority of our 42 producers have their manufacturing facilities in China and Vietnam.

Number and origin of production for the 2016 Summer and Winter Collections

Create your own infographicsProduction country shares by the quantity of produced goods

Create your own infographicsMaterials – Performance meets Ecology

Most of our materials are bought by our producers in accordance with our specifications for quality, colors, amounts, and from the material manufacturers that we have already carefully selected (nominated). So in addition to knowing all of our producers, we also know all of our material suppliers.

Dialog with these material suppliers whose substances and ingredients we nominate is ongoing and extensive. We have worked together with many of them for years and are developing new materials specifically for VAUDE.

In part, our producers are using local materials suppliers for small parts. We now know all of these "local supply" suppliers and have integrated them in our monitoring process for hazardous substances; we provide training on how to deal with chemicals and regularly analyze their chemical testing. With coordinated efforts between quality management, purchasing and our team, we are implementing measures that help suppliers achieve improvement.

Empowerment for better environmental protection

Our material suppliers produce a wide range of textile fabrics such as fabrics or knitted fabrics. They buy fibers and components such as dyes from their suppliers. The woven, knit or warp-knit fabric is then "finished" with chemical or mechanical processes such as dyeing, laminating, applying substances for UV protection or waterproofing.

By and large, material manufacturing is a machine process. Environmental aspects such as the use of energy, water, wastewater and chemicals are especially vital in this part of the process. You can read more here about how we are helping our suppliers to create effective environmental management systems.

Number and location of our material manufacturers

VAUDE has about 150 material manufacturers in total (fabrics, components such as buttons as well as other locally sourced small components).

Number and main location of material suppliers for the 2016 Summer and Winter Collections

Create your own infographicsHigh standards with the bluesign® system and Fair Wear Foundation

VAUDE has worked with most producers and material suppliers for years. We evaluate producers systematically in accordance with the following criteria:

- Product quality

- Delivery times

- Production amounts in quantity and sales value

- Fair Wear Foundation Audits

- Management of harmful substances

We achieve a high standard of safety in our supply chain with the bluesign® system and the Fair Wear Foundation (FWF).

Nevertheless, we are in the process of building our own systematic evaluation system for all suppliers. Our goal is not only complete transparency of the origin of all materials processed by VAUDE throughout the various upstream stages of the supply chain, but also a complete evaluation system for producers and suppliers according to environmental and social criteria.

| GRI: | G4-12 |

| GRI: | G4-13 |

| GRI: | G4-EN32 |

| GRI: | G4-EN33 |