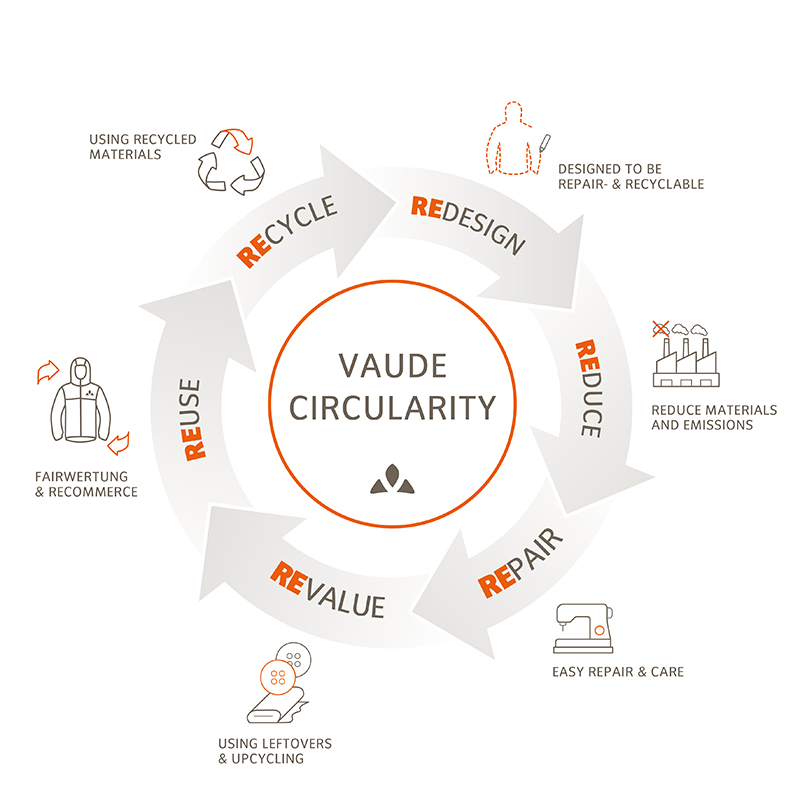

Our path towards the circular economy – extending lifespan, closing circuits, and establishing circular business models

Our products are designed to be used in the great outdoors, and we aim to minimize their impact on the environment. To keep our ecological footprint low, we strive to act in a resource-efficient manner throughout the entire product lifecycle, including the phases of manufacturing, use, and disposal. Our focus is on transforming linear processes and business models into a true circular economy. Through circular systems, durable products, professional repairs, circular business models, and recycling of discarded products, we can prolong the use phase of resources already in circulation and utilize them as a basis for new products. This allows us to reduce our dependence on finite, fossil resources. By doing so, we make a valuable contribution to climate and environmental protection.

Nature is our source of inspiration

There is no better model for circular systems than nature itself. Our natural ecosystems operate in intricate, interconnected cycles. They follow the principle of reuse, where there is no waste or inefficiency. Instead, everything is kept in continuous circulation through endless cycles, utilization sequences, and optimally adapted interrelationships. Nature serves as the perfect prototype for true circular systems, which is why we draw our inspiration from it.

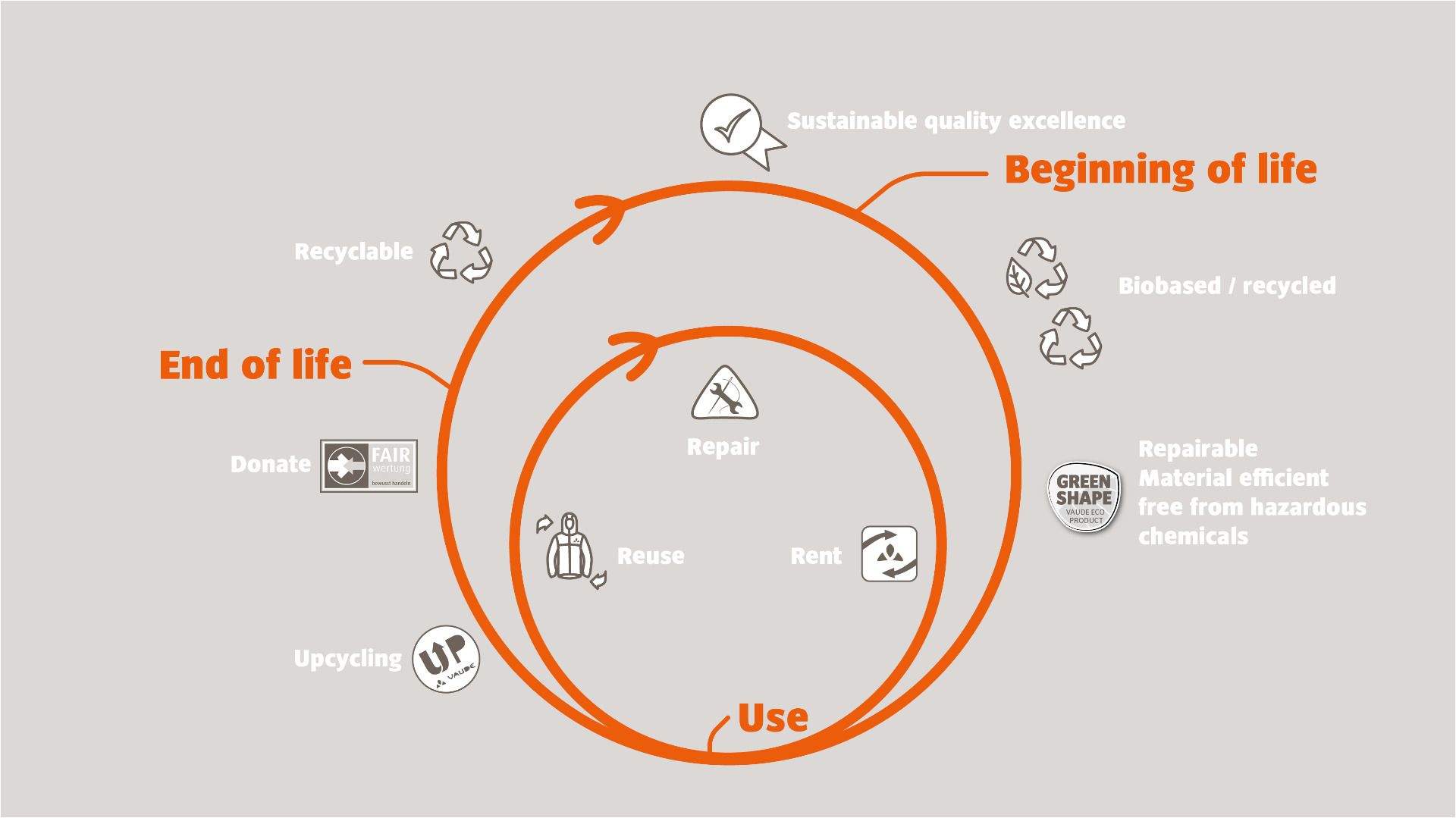

Circular economy in the product lifecycle

There are many opportunities for implementing circular systems in various stages of the product lifecycle. We focus on three phases: the "beginning of life," which involves the manufacturing of our products, the usage phase by stores and consumers, and the "end of life" phase, which refers to the product's disposal or recycling.

»The circular economy is one of the major challenges of our time. Even though the path ahead may be rocky and often unknown, it is incredibly important to embark upon it. We must use our limited resources more efficiently.«

Material selection - biobased or recycled

Recycled materials are not obtained from new resources but have already had a previous "life" in a different form. The raw resources contained in these materials are not simply discarded but are recycled through various processes to be reused within the circular economy. The recycled materials we use include polyester from PET recycling, polyamide from tire recycling, polyamide from fishing net recycling, recycled cotton, and recycled down. Learn more about it here.

Processing - the foundation for future recycling

Ideally, for products to be effectively recycled in the future, they need to be made from a single material (monomaterial) to ensure purity. We recognized this in the 1990s and established our Ecolog Recycling Network in 1994. Ecolog products were made entirely of polyester and were easily recyclable. However, the challenge was that very few products were returned to the recycling system, leading us to discontinue Ecolog. Learn more about it here.

In most cases, products are not monomaterial but consist of multiple materials combined by spinning, sewing, welding, or bonding. Ideally, the different materials should be processed in a way that allows for efficient separation without quality loss during recycling. This enables optimal recovery and reuse. However, conflicts often arise regarding the desired functionality of the products. Like many others, we also use a mix of different materials in a significant portion of our products. This allows us to combine different material properties effectively or is necessary to fulfill specific usage requirements.

For example, when manufacturing bike shorts, elastane is added to ensure optimal freedom of movement. Wool has excellent thermal regulation properties but has poor abrasion resistance and dries less efficiently than synthetic fibers. Therefore, blends of wool with other materials are often used to increase the durability and lifespan of products. More complex textile products, such as shoes with soles, uppers, linings, and closures, or a backpack that requires foam and plastics for the suspension system, consist of multiple components that need to be well bonded together to ensure high functionality and long-lasting use.

This complexity makes the subsequent separation and recycling process challenging. Currently, there are often insufficient methods available to separate used textiles into pure material streams. We are actively involved in various networks and research projects to develop cross-industry textile recycling solutions. Learn more about it in the "End of Life" section.

In our VAUDE Material Policy, we assess all the materials we use based on their recyclability and the current state of recycling infrastructure. Any materials that are not (or only very difficult to) recyclable, such as elastane and polyurethane, are only used when their functionality is necessary for the product.

With our Rethink! Collection, we are taking the next step towards a circular economy starting in summer 2024.

VAUDE products reimagined for circular concepts to reduce waste and enable recycling: the Rethink! Collection.

Rethinking - that's what we’re aiming for with our circular concept product. They are streamlined to a single type of raw material: all components are made of recycled polyester, and parts made of other materials are detachable. This allows these products to easily be transformed into new raw materials. Furthermore, we’re continuously optimizing the patterns to efficiently utilize materials, reduce waste, and minimize CO2 emissions. Finally, the products are designed to be durable and easily repairable if needed.

Recycling and keeping outdoor products within the circular economy is a significant challenge. However, we are changing our approach! With our RETHINK! products, we are taking the initial steps towards recyclability by transitioning our products in line with the principles of the circular economy:

- Zippers and zipper tapes have been transitioned to PET polyester for recyclability.

- Instead of using stretch-blend fabrics, we use specially sorted yarns made of recycled PET polyester.

- For circularity, we have switched from typical polyamide to PET polyester for items such as Velcro fasteners.

- Backpacks have a PET coating instead of TPU for material purity - an innovation.

- Non-PET components are color-coded and easily replaceable.

- Instead of a conventional backpack back panel made from various materials, we use a 100% PET back panel.

- To ensure material purity, we avoid elastic fabrics made from polyamide and have outfitted side pockets and organizers with compression straps.

- A simple 4-hole button made of recycled PET polyester replaces a metal snap button, making it easy to repair and in line with the principles of the circular economy.

Usage phase - for as long as possible

A significant portion of the ecological footprint of consumer goods is generated during the usage phase. Many products only become truly sustainable when they remain in use for as long as possible. The principle is simple: as long as a product can be used, there is no need to manufacture a new one. Shared usage is also ideal for items that are not frequently needed. For example, if a tent or backpack is used by more than one person, there is no need for each person to acquire their own – and this conserves valuable resources in many ways.

Circular business models: Rental service, second-hand, and clothing donations

To prevent products from sitting unused in closets, basements, or attics because they may not be frequently used, we offer the option to rent them through the VAUDE Rent program. Renting has the advantage, especially for large items, of not requiring storage space, it saves on purchasing costs, and when the products are returned to us, we can ensure professional care and maintenance. Renting can also be a great way to avoid making unnecessary purchases and allow customers to try out products before making a purchasing commitment. You can find more information here.

Buying used products also contributes to the reuse of items such as clothing that is no longer worn or children's clothing that has been outgrown. Buying second-hand provides opportunities for eco-friendly shopping, as it avoids the need to purchase new products and their resource-intensive production. We also want to ensure that our products remain in circulation through second-hand distribution channels. Therefore, we are currently working intensively on establishing a re-commerce platform.

Furthermore, we’re collaborating with Fairwertung, a nonprofit organization specializing in clothing donations. They ensure the fair reuse of used textiles and, if possible, recycle textiles that are no longer usable into insulation or cleaning materials (see End of Life).

Care & Repair

Upcycling

When a material or product no longer serves its original purpose and can’t be repaired, we strive to give it new life in our upcycling workshop. Not everything that ends up in the waste bin is truly waste. We firmly believe that through creative ideas, valuable resources can be transformed from what may seem like trash into unique and remarkable creations. That's why we’ve established our upcycling workshop and with our new Upcycling Collection, we can rescue our remnant materials from ending up in the landfill.

Learn more about it here.

End of Life - Recycling of discarded products

With the European Green Deal, the EU has committed to achieving climate neutrality by 2050. The accompanying roadmap for planned legislation introduces various measures, such as the "Circular Economy Action Plan," which focuses on sustainable product design and circular economy in production processes. For the textile sector, the EU Commission proposed the "EU Strategy for Sustainable and Circular Textiles" at the end of March 2022. This strategy includes design requirements for textiles that are durable, repairable, and recyclable, with a high proportion of recycled materials. Additionally, it aims to promote circular business models and replace disposable clothing with circular textiles.

We welcome these measures because, unfortunately, most textiles, like many consumer goods, still follow a linear usage pattern. This means that when they reach the end of their life and cannot be reused through second-hand sales or clothing donations, they end up in the general waste stream.

In the EU, it is estimated that around 5.8 million tons of clothing are discarded annually, equivalent to 11.3 kg per person. Only about 1% of clothing is recycled into new textiles through textile recycling processes. This is mainly due to the requirement for textiles to be as pure as possible for effective recycling, and cross-industry collection and recycling systems are still being developed.

Currently, a portion of collected used clothing is repurposed as insulation in cars, cleaning rags, or painter's fleece. However, approximately 87% of textiles produced in the EU end up in landfills or are thermally treated in waste incineration plants. Valuable resources remain unused or are even destroyed. Thermal treatment releases the carbon trapped in fossil resources as CO2 emissions into the atmosphere, with negative consequences for our climate.

Project Partnerships: Accelerating Circularity & Textile Partnership

To accelerate the use of used clothing and textile waste as raw materials for new textiles, we are partnering with Accelerating Circularity, a US-based nonprofit organization that aims to achieve textile-to-textile recycling. Through industry-wide collaboration among partners across the textile value chain, from material manufacturers to textile producers and collection companies, a market-ready infrastructure for textile recycling is being developed using a digital platform. Initial trials using polyester textiles aim to provide insights into how textile recycling can be realized on a large scale through mechanical and/or chemical processes.

As a member of the Partnership for Sustainable Textiles in Germany, we are also committed to industry-wide solutions that focus on textile recycling.